PC 3016 NT VARIOVARIO® chemistry pumping unit

Overview

- VARIO®: Automatic adjustment of the vacuum level throughout the process for high process reproducibility and unattended operation

- very high pumping speed even at low vacuum levels

- systems +EK and PC 3016 NT VARIO: excellent environmental friendliness due to efficient solvent recovery

- short process times due to zero-fluctuation (hysteresis-free) vacuum control, even for large amounts of vapor

- easily operated CVC 3000 vacuum controller with clear text menus and integrated venting valve

Ultimate vacuum

70 mbar

Ultimate vacuum with gas ballast

100 mbar

Max. pumping speed 50 Hz

19.3 m3/h

VARIO® chemistry pumping unit in action

These powerful pumps feature exceptionally high pumping speed. VARIO® pumping units provide precise vacuum control by adjusting the diaphragm pump´s motor speed. They feature fully automatic evaporation control at the push of a button. The PC 3016 NT VARIO pumping unit is a proven concept for evaporations with large amounts of solvents. The inlet separator (AK) retains particles and liquid droplets, the waste vapor condenser at the outlet (EK) is highly efficient and compact. The condenser enables near-100-percent solvent recovery, efficient recycling, and active protection of the environment. Eight-cylinder NT pumps features quiet operation with smooth, easy-to-clean surfaces. The extraordinarily high pumping speed reduces the process time significantly and permits the usage of these pumps to support large vacuum networks, or in life science labs where high gas throughput is needed, but only a modest vacuum level. VARIO® provides hysteresis-free vacuuum control. Typical applications with such characteristics include evaporation processes with low boiling solvents. Evaporation processes can be run fully automatically and with short process times and high sensitivity at the same time. The VARIO® control ensures high process reliability by preventing superheating and foaming. The inlet separator of the PC 3016 NT VARIO® makes this pump well-suited to rough operating conditions and enables efficient solvent recovery. These accessories such as the optional separator at the inlet (AK) for pump protection and the exhaust waste vapor condenser (EK), can be mounted to the pumps later, if the need arises.

Technical data and graphs

| Max. pumping speed 50 Hz | 19.3 m3/h | |

| Max. pumping speed 60 Hz | 11.4 cfm | |

| Ultimate vacuum | 70 mbar / 53 torr | |

| Ultimate vacuum with gas ballast | 100 mbar / 75 torr | |

| Number of heads | 8 | |

| Number of stages | 1 | |

| Vacuum controller | CVC 3000 | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | Small flange KF DN 25 / hose nozzle DN 15 mm | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Coolant connection | 2 x hose nozzle DN 6-8 mm | |

| Rated motor power | 0.53 kW | |

| Protection class IEC 60529 | IP 40 | |

| Dimension L in mm | 616 mm | |

| Dimension B in mm | 387 mm | |

| Dimension H in mm | 420 mm | |

| Weight | 29.7 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 47 dBA | |

| NRTL certification | No | |

| Items supplied | Pumping unit completely mounted, ready for use, with manual | |

| Rated mains voltage range 1 | 200-230 V | |

| Mains frequency 1 | 50-60 Hz |

Equipment

-

![Clamping ring, aluminum, KF DN 20/25]() KF DN 20/25 Clamping ring for small flange

KF DN 20/25 Clamping ring for small flange- Quick link

- Nominal width KF DN 20/25

- Material Aluminum

![External centring ring, PBT,sealing ring FPM, KF DN 20/25]() KF DN 20/25 External centring ring for small flange

KF DN 20/25 External centring ring for small flange- Nominal width KF DN 20/25

- Material PBT

- Material sealing FKM

![PVC tubing with spiral, KF DN 25/1000 mm]() KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges

KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges- PVC with stainless steel spiral

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

![Fluid level sensorfor round bottom flask 500 mlcertification (NRTL): C/US]() 500 ml Fluid level sensor for round bottom flask 500 ml

500 ml Fluid level sensor for round bottom flask 500 ml- Mains plug VACUU·BUS®

- Cable length 2 m

![Coolant valve VKW-B, VACUU·BUS,DN 1,5 mm, inlet G3/4" / G1/2",outlet nozzle 6 mm, cable length 2 mcertification (NRTL): C/US]() VKW-B Cooling water valve

VKW-B Cooling water valve- Mains plug VACUU·BUS®

- Nominal width 1.5 mm

![Air admittance valve VB M-B KF DN16 /G1/4 with hose nipple G1/4" - 6/10 mm,VACUU·BUS, certification (NRTL): C/US]() VB M-B Air admittance valve

VB M-B Air admittance valve- Electromagnetic solenoid valve

- High prevention against wear

- Leak rate 1 x 10-3 min l/s

![Set of diaphragms and valvesfor ME 8C NT,ME 16C NT (2x),PC 3016 NT VARIO select (2x)]()

This might also interest you

-

![ME 1C Chemistry diaphragm pump]() ME 1C Chemistry diaphragm pump

ME 1C Chemistry diaphragm pump- Ultimate vacuum 100 mbar

- Pumping speed 0.7 m3/h

- Oilfree & chemically resistant

![ME 2C NT Chemistry diaphragm pump]() ME 2C NT Chemistry diaphragm pump

ME 2C NT Chemistry diaphragm pump- Ultimate vacuum 70 mbar

- Pumping speed 2.1 m3/h

- Oilfree & chemically resistant

![ME 4C NT Chemistry diaphragm pump]() ME 4C NT Chemistry diaphragm pump

ME 4C NT Chemistry diaphragm pump- Ultimate vacuum 70 mbar

- Pumping speed 3.9 m3/h

- Oilfree & chemically resistant

![ME 8C NT Chemistry diaphragm pump]() ME 8C NT Chemistry diaphragm pump

ME 8C NT Chemistry diaphragm pump- Ultimate vacuum 70 mbar

- Pumping speed 7.1 m3/h

- Oilfree & chemically resistant

![ME 16C NT Chemistry diaphragm pump]() ME 16C NT Chemistry diaphragm pump

ME 16C NT Chemistry diaphragm pump- Ultimate vacuum 70 mbar

- Pumping speed 16.3 m3/h

- Oilfree & chemically resistant

VARIO® chemistry pumping unit in action

These powerful pumps feature exceptionally high pumping speed. VARIO® pumping units provide precise vacuum control by adjusting the diaphragm pump´s motor speed. They feature fully automatic evaporation control at the push of a button. The PC 3016 NT VARIO pumping unit is a proven concept for evaporations with large amounts of solvents. The inlet separator (AK) retains particles and liquid droplets, the waste vapor condenser at the outlet (EK) is highly efficient and compact. The condenser enables near-100-percent solvent recovery, efficient recycling, and active protection of the environment. Eight-cylinder NT pumps features quiet operation with smooth, easy-to-clean surfaces. The extraordinarily high pumping speed reduces the process time significantly and permits the usage of these pumps to support large vacuum networks, or in life science labs where high gas throughput is needed, but only a modest vacuum level. VARIO® provides hysteresis-free vacuuum control. Typical applications with such characteristics include evaporation processes with low boiling solvents. Evaporation processes can be run fully automatically and with short process times and high sensitivity at the same time. The VARIO® control ensures high process reliability by preventing superheating and foaming. The inlet separator of the PC 3016 NT VARIO® makes this pump well-suited to rough operating conditions and enables efficient solvent recovery. These accessories such as the optional separator at the inlet (AK) for pump protection and the exhaust waste vapor condenser (EK), can be mounted to the pumps later, if the need arises.

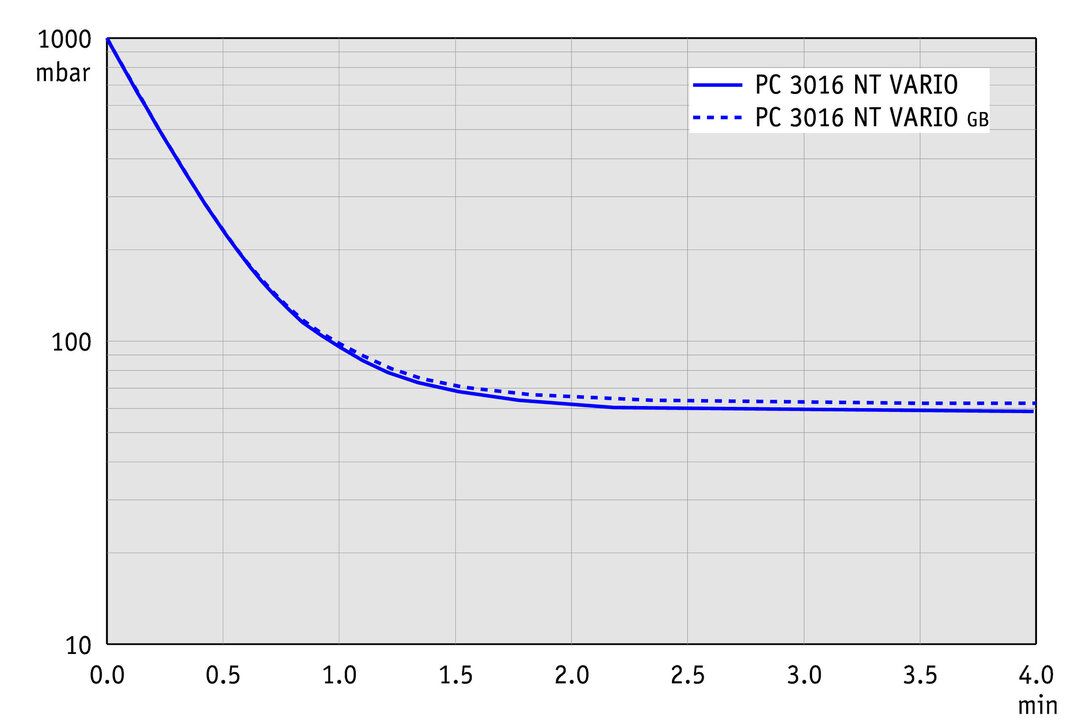

Technical data and graphs

Max. pumping speed 50 Hz 19.3 m3/h Max. pumping speed 60 Hz 11.4 cfm Ultimate vacuum 70 mbar / 53 torr Ultimate vacuum with gas ballast 100 mbar / 75 torr Number of heads 8 Number of stages 1 Vacuum controller CVC 3000 Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Inlet connection Small flange KF DN 25 / hose nozzle DN 15 mm Outlet connection Hose nozzle DN 8-10 mm Coolant connection 2 x hose nozzle DN 6-8 mm Rated motor power 0.53 kW Protection class IEC 60529 IP 40 Dimension L in mm 616 mm Dimension B in mm 387 mm Dimension H in mm 420 mm Weight 29.7 kg Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) 47 dBA NRTL certification No Items supplied Pumping unit completely mounted, ready for use, with manual Rated mains voltage range 1 200-230 V Mains frequency 1 50-60 Hz  für Zoom klicken

für Zoom klicken

Pump down graph 50 Hz (100 l volume)

Equipment

-

![Clamping ring, aluminum, KF DN 20/25]() KF DN 20/25 Clamping ring for small flange

KF DN 20/25 Clamping ring for small flange- Quick link

- Nominal width KF DN 20/25

- Material Aluminum

![External centring ring, PBT,sealing ring FPM, KF DN 20/25]() KF DN 20/25 External centring ring for small flange

KF DN 20/25 External centring ring for small flange- Nominal width KF DN 20/25

- Material PBT

- Material sealing FKM

![PVC tubing with spiral, KF DN 25/1000 mm]() KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges

KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges- PVC with stainless steel spiral

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

![Fluid level sensorfor round bottom flask 500 mlcertification (NRTL): C/US]() 500 ml Fluid level sensor for round bottom flask 500 ml

500 ml Fluid level sensor for round bottom flask 500 ml- Mains plug VACUU·BUS®

- Cable length 2 m

![Coolant valve VKW-B, VACUU·BUS,DN 1,5 mm, inlet G3/4" / G1/2",outlet nozzle 6 mm, cable length 2 mcertification (NRTL): C/US]() VKW-B Cooling water valve

VKW-B Cooling water valve- Mains plug VACUU·BUS®

- Nominal width 1.5 mm

![Air admittance valve VB M-B KF DN16 /G1/4 with hose nipple G1/4" - 6/10 mm,VACUU·BUS, certification (NRTL): C/US]() VB M-B Air admittance valve

VB M-B Air admittance valve- Electromagnetic solenoid valve

- High prevention against wear

- Leak rate 1 x 10-3 min l/s

![Set of diaphragms and valvesfor ME 8C NT,ME 16C NT (2x),PC 3016 NT VARIO select (2x)]()

This might also interest you

-

![ME 1C Chemistry diaphragm pump]() ME 1C Chemistry diaphragm pump

ME 1C Chemistry diaphragm pump- Ultimate vacuum 100 mbar

- Pumping speed 0.7 m3/h

- Oilfree & chemically resistant

![ME 2C NT Chemistry diaphragm pump]() ME 2C NT Chemistry diaphragm pump

ME 2C NT Chemistry diaphragm pump- Ultimate vacuum 70 mbar

- Pumping speed 2.1 m3/h

- Oilfree & chemically resistant

![ME 4C NT Chemistry diaphragm pump]() ME 4C NT Chemistry diaphragm pump

ME 4C NT Chemistry diaphragm pump- Ultimate vacuum 70 mbar

- Pumping speed 3.9 m3/h

- Oilfree & chemically resistant

![ME 8C NT Chemistry diaphragm pump]() ME 8C NT Chemistry diaphragm pump

ME 8C NT Chemistry diaphragm pump- Ultimate vacuum 70 mbar

- Pumping speed 7.1 m3/h

- Oilfree & chemically resistant

![ME 16C NT Chemistry diaphragm pump]() ME 16C NT Chemistry diaphragm pump

ME 16C NT Chemistry diaphragm pump- Ultimate vacuum 70 mbar

- Pumping speed 16.3 m3/h

- Oilfree & chemically resistant