PC 3012 NT VARIO selectVARIO® chemistry pumping unit

Overview

- VACUU·SELECT vacuum controller with graphical user interface and predefined applications simplifies work in the laboratory

- automatic boiling point detection and adjustment of the vacuum for short process times

- meets high vacuum requirements for large quantities of most high boiling solvents

- extraordinary diaphragm life for minimum operational and servicing costs

- excellent environmental compatibility through low energy consumption and efficient solvent recovery

Ultimate vacuum

1.5 mbar

Ultimate vacuum with gas ballast

3 mbar

Max. pumping speed 50 Hz

14.3 m3/h

VARIO® chemistry pumping unit in action

The PC 3012 NT VARIO select pumping unit precisely controls the vacuum level in order to achieve unparalleled process control. With its combination of high pumping speed and deep ultimate vacuum, this pump is suitable for demanding applications with even high boiling point solvents. This pump is regularly used to support floor-standing rotary evaporators, vacuum drying ovens, distillation columns, and other similar work in miniplants, kilo labs, and scale-up facilities. The integrated VACUU·SELECT controller provides an easy-to-use, application based interface that covers all common lab applications. The VACUU·SELECT controller has you covered. Use manual set-point-control for simple processes, run fully automated distillations, or create your own application with simple drag-and-drop editing. For solvent evaporation, the VACUU·SELECT controller continuously detects the boiling point and automatically adjusts the vacuum process as necessary. In addition, the VARIO control maintains the desired vacuum level by running the motor only as fast as necessary. This prevents bumping and foaming, makes the pump whisper quiet, and extends maintenance intervals. The inlet separator, made of glass with a robust protective coating, prevents particles and liquid droplets from entering the pump, preventing damage and extending pump life. And the exhaust vapor condenser allows for nearly complete recovery of solvents when used with a chilled water line or recirculating chiller for economical recycling and environmental protection.

Technical data and graphs

| Max. pumping speed 50 Hz | 14.3 m3/h | |

| Max. pumping speed 60 Hz | 8.4 cfm | |

| Ultimate vacuum | 1.5 mbar / 1.1 torr | |

| Ultimate vacuum with gas ballast | 3 mbar / 2.2 torr | |

| Number of heads | 8 | |

| Number of stages | 3 | |

| Vacuum controller | VACUU·SELECT | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | Small flange KF DN 25 / hose nozzle DN 15 mm | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Coolant connection | 2 x hose nozzle DN 6-8 mm | |

| Rated motor power | 0.53 kW | |

| Protection class IEC 60529 | IP 40 | |

| Dimension L in mm | 616 mm | |

| Dimension B in mm | 387 mm | |

| Dimension H in mm | 450 mm | |

| Weight | 29.7 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 47 dBA | |

| ATEX conformity | II 3/- G Ex h IIC T3 Gc X Internal Atm. only | |

| NRTL certification | No | |

| Items supplied | Pumping unit completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 200-230 V | |

| Mains frequency 1 | 50-60 Hz |

Downloads

Equipment

-

![VACUU·SELECT user management]() VACUU·SELECT User Management Function extension for VACUU·SELECT controller

VACUU·SELECT User Management Function extension for VACUU·SELECT controller- Flexible and individual permissions

- Ensure consistent process parameters

- Customized working environment

![Clamping ring, aluminum, KF DN 20/25]() KF DN 20/25 Clamping ring for small flange

KF DN 20/25 Clamping ring for small flange- Quick link

- Nominal width KF DN 20/25

- Material Aluminum

![External centring ring, PBT,sealing ring FPM, KF DN 20/25]() KF DN 20/25 External centring ring for small flange

KF DN 20/25 External centring ring for small flange- Nominal width KF DN 20/25

- Material PBT

- Material sealing FKM

![PVC tubing with spiral, KF DN 25/1000 mm]() KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges

KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges- PVC with stainless steel spiral

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

![Fluid level sensorfor round bottom flask 500 mlcertification (NRTL): C/US]() 500 ml Fluid level sensor for round bottom flask 500 ml

500 ml Fluid level sensor for round bottom flask 500 ml- Mains plug VACUU·BUS®

- Cable length 2 m

![Coolant valve VKW-B, VACUU·BUS,DN 1,5 mm, inlet G3/4" / G1/2",outlet nozzle 6 mm, cable length 2 mcertification (NRTL): C/US]() VKW-B Cooling water valve

VKW-B Cooling water valve- Mains plug VACUU·BUS®

- Nominal width 1.5 mm

![Air admittance valve VB M-B KF DN16 /G1/4 with hose nipple G1/4" - 6/10 mm,VACUU·BUS, certification (NRTL): C/US]() VB M-B Air admittance valve

VB M-B Air admittance valve- Electromagnetic solenoid valve

- High prevention against wear

- Leak rate 1 x 10-3 min l/s

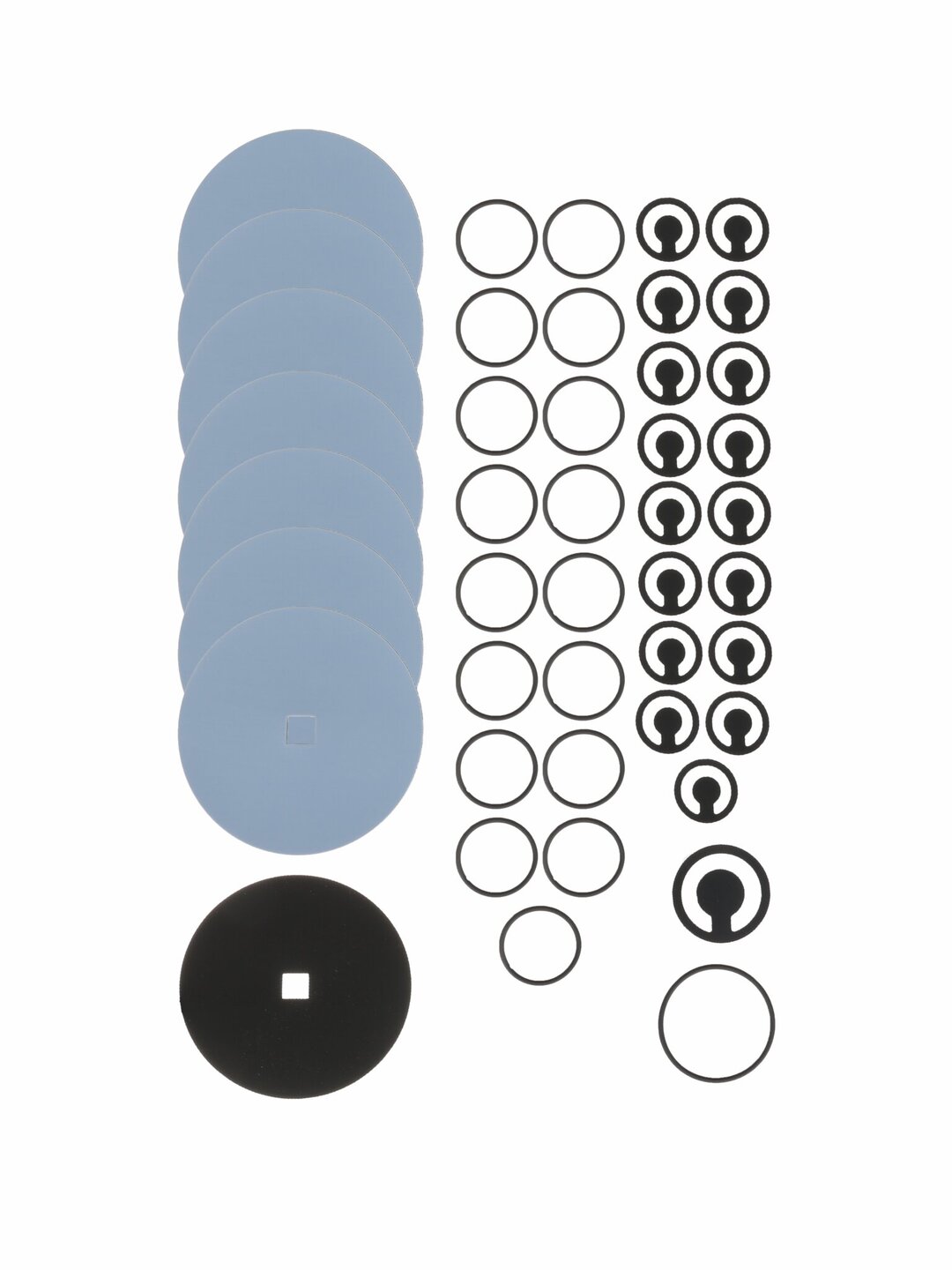

![Set of diaphragms and valvesfor MD 12C NT, MV 10C NT]() MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves

MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves- Complete kit

- Original spare parts

- Easy assembly

This might also interest you

-

![PC 3001 VARIO select VARIO® chemistry pumping unit]() PC 3001 VARIO select VARIO® chemistry pumping unit

PC 3001 VARIO select VARIO® chemistry pumping unit- Ultimate vacuum 2.0 mbar

- Pumping speed 2 m3/h

- Oilfree & chemically resistant

![Chemistry diaphragm pump MD 1C]() MD 1C Chemistry diaphragm pump

MD 1C Chemistry diaphragm pump- Ultimate vacuum 2 mbar

- Pumping speed 1.3 m3/h

- Oilfree & chemically resistant

![MD 4C NT Chemistry diaphragm pump]() MD 4C NT Chemistry diaphragm pump

MD 4C NT Chemistry diaphragm pump- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

![MD 4C VARIO select VARIO® chemistry diaphragm pump]() MD 4C VARIO select VARIO® chemistry diaphragm pump

MD 4C VARIO select VARIO® chemistry diaphragm pump- Ultimate vacuum 1.5 mbar

- Pumping speed 4.6 m3/h

- Oilfree & chemically resistant

![MD 4C NT +2AK Chemistry vacuum system]() MD 4C NT +2AK Chemistry vacuum system

MD 4C NT +2AK Chemistry vacuum system- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

![MD 4C NT +AK+EK Chemistry vacuum system]() MD 4C NT +AK+EK Chemistry vacuum system

MD 4C NT +AK+EK Chemistry vacuum system- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

VARIO® chemistry pumping unit in action

The PC 3012 NT VARIO select pumping unit precisely controls the vacuum level in order to achieve unparalleled process control. With its combination of high pumping speed and deep ultimate vacuum, this pump is suitable for demanding applications with even high boiling point solvents. This pump is regularly used to support floor-standing rotary evaporators, vacuum drying ovens, distillation columns, and other similar work in miniplants, kilo labs, and scale-up facilities. The integrated VACUU·SELECT controller provides an easy-to-use, application based interface that covers all common lab applications. The VACUU·SELECT controller has you covered. Use manual set-point-control for simple processes, run fully automated distillations, or create your own application with simple drag-and-drop editing. For solvent evaporation, the VACUU·SELECT controller continuously detects the boiling point and automatically adjusts the vacuum process as necessary. In addition, the VARIO control maintains the desired vacuum level by running the motor only as fast as necessary. This prevents bumping and foaming, makes the pump whisper quiet, and extends maintenance intervals. The inlet separator, made of glass with a robust protective coating, prevents particles and liquid droplets from entering the pump, preventing damage and extending pump life. And the exhaust vapor condenser allows for nearly complete recovery of solvents when used with a chilled water line or recirculating chiller for economical recycling and environmental protection.

Technical data and graphs

Max. pumping speed 50 Hz 14.3 m3/h Max. pumping speed 60 Hz 8.4 cfm Ultimate vacuum 1.5 mbar / 1.1 torr Ultimate vacuum with gas ballast 3 mbar / 2.2 torr Number of heads 8 Number of stages 3 Vacuum controller VACUU·SELECT Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Inlet connection Small flange KF DN 25 / hose nozzle DN 15 mm Outlet connection Hose nozzle DN 8-10 mm Coolant connection 2 x hose nozzle DN 6-8 mm Rated motor power 0.53 kW Protection class IEC 60529 IP 40 Dimension L in mm 616 mm Dimension B in mm 387 mm Dimension H in mm 450 mm Weight 29.7 kg Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) 47 dBA ATEX conformity II 3/- G Ex h IIC T3 Gc X Internal Atm. only NRTL certification No Items supplied Pumping unit completely mounted, ready for use, with manual. Rated mains voltage range 1 200-230 V Mains frequency 1 50-60 Hz  für Zoom klicken

für Zoom klicken

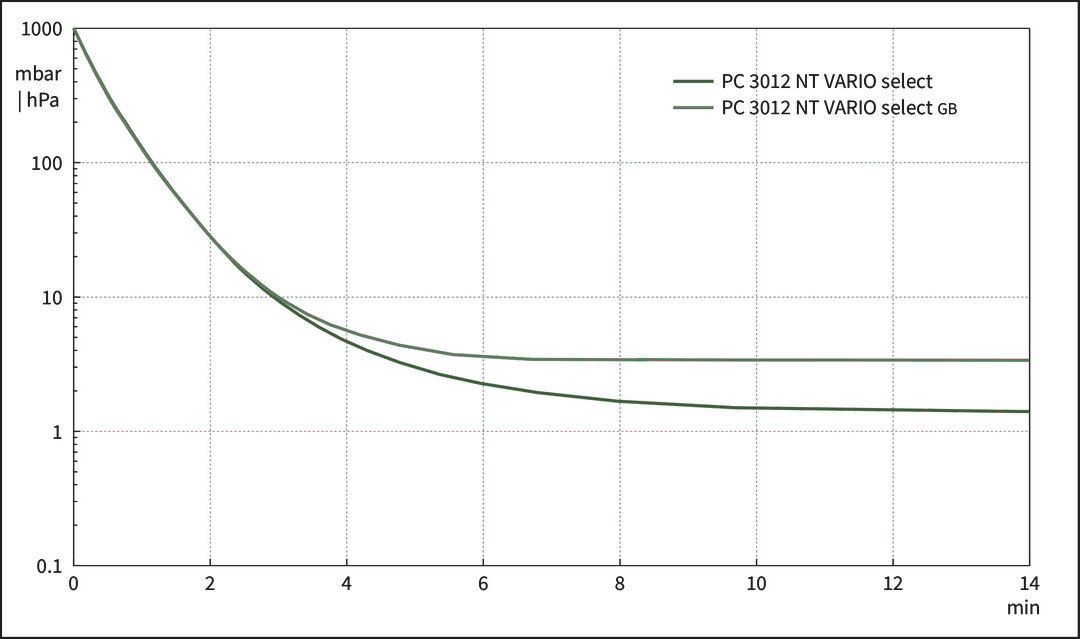

Pump down graph 50 Hz (100 l volume)

Downloads

VARIO chemistry pumping unit,PC 3012 NT VARIO select, 200-230 V / 50-60Hz,IN mains cablePC 3012 NT VARIO selectVARIO® chemistry pumping unitDownload Download Download Download DownloadTechnical data sheetData sheet PDF 4 MB 4 MB 4.1 MB 4 MB 4.1 MBDownload Download Download Download Download Download Download Download Download Download Download Download Download Download DownloadManual vacuum pumpManual PDF 19.4 MB 20.9 MB 20.2 MB 20.1 MB 20.1 MB 20.1 MB 20.2 MB 20.1 MB 20.1 MB 20.1 MB 20.1 MB 20.1 MB 20.2 MB 20.1 MB 20.1 MBDownload Download Download Download Download Download Download Download Download Download Download Download Download Download Download DownloadManual vacuum gauge / controllerManual PDF 17.4 MB 17.1 MB 17.5 MB 17.4 MB 17.4 MB 17.5 MB 17.4 MB 17.5 MB 17.4 MB 17.8 MB 17.5 MB 17.5 MB 17.4 MB 17.5 MB 17.5 MB 17.3 MBEquipment

-

![VACUU·SELECT user management]() VACUU·SELECT User Management Function extension for VACUU·SELECT controller

VACUU·SELECT User Management Function extension for VACUU·SELECT controller- Flexible and individual permissions

- Ensure consistent process parameters

- Customized working environment

![Clamping ring, aluminum, KF DN 20/25]() KF DN 20/25 Clamping ring for small flange

KF DN 20/25 Clamping ring for small flange- Quick link

- Nominal width KF DN 20/25

- Material Aluminum

![External centring ring, PBT,sealing ring FPM, KF DN 20/25]() KF DN 20/25 External centring ring for small flange

KF DN 20/25 External centring ring for small flange- Nominal width KF DN 20/25

- Material PBT

- Material sealing FKM

![PVC tubing with spiral, KF DN 25/1000 mm]() KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges

KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges- PVC with stainless steel spiral

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

![Fluid level sensorfor round bottom flask 500 mlcertification (NRTL): C/US]() 500 ml Fluid level sensor for round bottom flask 500 ml

500 ml Fluid level sensor for round bottom flask 500 ml- Mains plug VACUU·BUS®

- Cable length 2 m

![Coolant valve VKW-B, VACUU·BUS,DN 1,5 mm, inlet G3/4" / G1/2",outlet nozzle 6 mm, cable length 2 mcertification (NRTL): C/US]() VKW-B Cooling water valve

VKW-B Cooling water valve- Mains plug VACUU·BUS®

- Nominal width 1.5 mm

![Air admittance valve VB M-B KF DN16 /G1/4 with hose nipple G1/4" - 6/10 mm,VACUU·BUS, certification (NRTL): C/US]() VB M-B Air admittance valve

VB M-B Air admittance valve- Electromagnetic solenoid valve

- High prevention against wear

- Leak rate 1 x 10-3 min l/s

![Set of diaphragms and valvesfor MD 12C NT, MV 10C NT]() MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves

MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves- Complete kit

- Original spare parts

- Easy assembly

This might also interest you

-

![PC 3001 VARIO select VARIO® chemistry pumping unit]() PC 3001 VARIO select VARIO® chemistry pumping unit

PC 3001 VARIO select VARIO® chemistry pumping unit- Ultimate vacuum 2.0 mbar

- Pumping speed 2 m3/h

- Oilfree & chemically resistant

![Chemistry diaphragm pump MD 1C]() MD 1C Chemistry diaphragm pump

MD 1C Chemistry diaphragm pump- Ultimate vacuum 2 mbar

- Pumping speed 1.3 m3/h

- Oilfree & chemically resistant

![MD 4C NT Chemistry diaphragm pump]() MD 4C NT Chemistry diaphragm pump

MD 4C NT Chemistry diaphragm pump- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

![MD 4C VARIO select VARIO® chemistry diaphragm pump]() MD 4C VARIO select VARIO® chemistry diaphragm pump

MD 4C VARIO select VARIO® chemistry diaphragm pump- Ultimate vacuum 1.5 mbar

- Pumping speed 4.6 m3/h

- Oilfree & chemically resistant

![MD 4C NT +2AK Chemistry vacuum system]() MD 4C NT +2AK Chemistry vacuum system

MD 4C NT +2AK Chemistry vacuum system- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

![MD 4C NT +AK+EK Chemistry vacuum system]() MD 4C NT +AK+EK Chemistry vacuum system

MD 4C NT +AK+EK Chemistry vacuum system- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant