MD 12C NT +AK+EKChemistry vacuum system

Overview

- outstanding chemical resistance and superior vapor tolerance

- reduced process time due to particularly high pumping speed even near ultimate vacuum

- whisper quiet and very low vibration

- very good ultimate vacuum even with open gas ballast valve for condensate purge

- efficient solvent recovery and inlet separator equip the MD 12C NT +AK+EK system for rough operating conditions

Ultimate vacuum

2 mbar

Ultimate vacuum with gas ballast

4 mbar

Max. pumping speed 50 Hz

12 m3/h

Chemistry vacuum system in action

These chemistry vacuum systems have a wide range of applications like evacuation, evaporation and pumping of gases and vapors. They provide particularly high pumping speed and are ideal for higher vacuum requirements, e.g., with high boiling solvents. The base MD 12C NT pump obtains a very good ultimate vacuum even with open gas ballast valve for condensate purge and delivers high pumping speed in a compact design. The pump design offers exceptionally high chemical resistance supporting almost universal usage in chemistry and pharmaceutics. The inlet separator (AK) retains particles and liquid droplets, the waste vapor condenser at the outlet (EK) is highly efficient and compact. The condenser enables near-100-percent solvent recovery, efficient recycling, and active protection of the environment.

Technical data and graphs

| Max. pumping speed 50 Hz | 12 m3/h | |

| Max. pumping speed 60 Hz | 7.0 cfm | |

| Ultimate vacuum | 2 mbar / 1.5 torr | |

| Ultimate vacuum with gas ballast | 4 mbar / 3 torr | |

| Number of heads | 8 | |

| Number of stages | 3 | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | Small flange KF DN 25 / hose nozzle DN 15 mm | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Coolant connection | 2 x hose nozzle DN 6-8 mm | |

| Rated motor power | 0.53 kW | |

| Rated motor speed at 50/60 Hz | 1650 min-1 | |

| Protection class IEC 60529 | IP 40 | |

| Dimension L in mm | 616 mm | |

| Dimension B in mm | 387 mm | |

| Dimension H in mm | 395 mm | |

| Weight | 28.9 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 50 dBA | |

| ATEX conformity | II 3/- G Ex h IIC T3 Gc X Internal Atm. only | |

| NRTL certification | No | |

| Items supplied | Pumping unit completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 200-230 V | |

| Mains frequency 1 | 50-60 Hz |

Downloads

Equipment

-

![Silencer with hose DN 8-10mm]() DN 8-10mm Silencer with hose 5cm

DN 8-10mm Silencer with hose 5cm![Clamping ring, aluminum, KF DN 20/25]() KF DN 20/25 Clamping ring for small flange

KF DN 20/25 Clamping ring for small flange- Quick link

- Nominal width KF DN 20/25

- Material Aluminum

![External centring ring, PBT,sealing ring FPM, KF DN 20/25]() KF DN 20/25 External centring ring for small flange

KF DN 20/25 External centring ring for small flange- Nominal width KF DN 20/25

- Material PBT

- Material sealing FKM

![PVC tubing with spiral, KF DN 25/1000 mm]() KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges

KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges- PVC with stainless steel spiral

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

![Small flange with hose nozzleKF DN 25/SW10, PP]() KF DN 25 / DN 10 mm Small flange with hose nozzle

KF DN 25 / DN 10 mm Small flange with hose nozzle- Hose shaft

- Nominal width KF DN 25

- Material PP

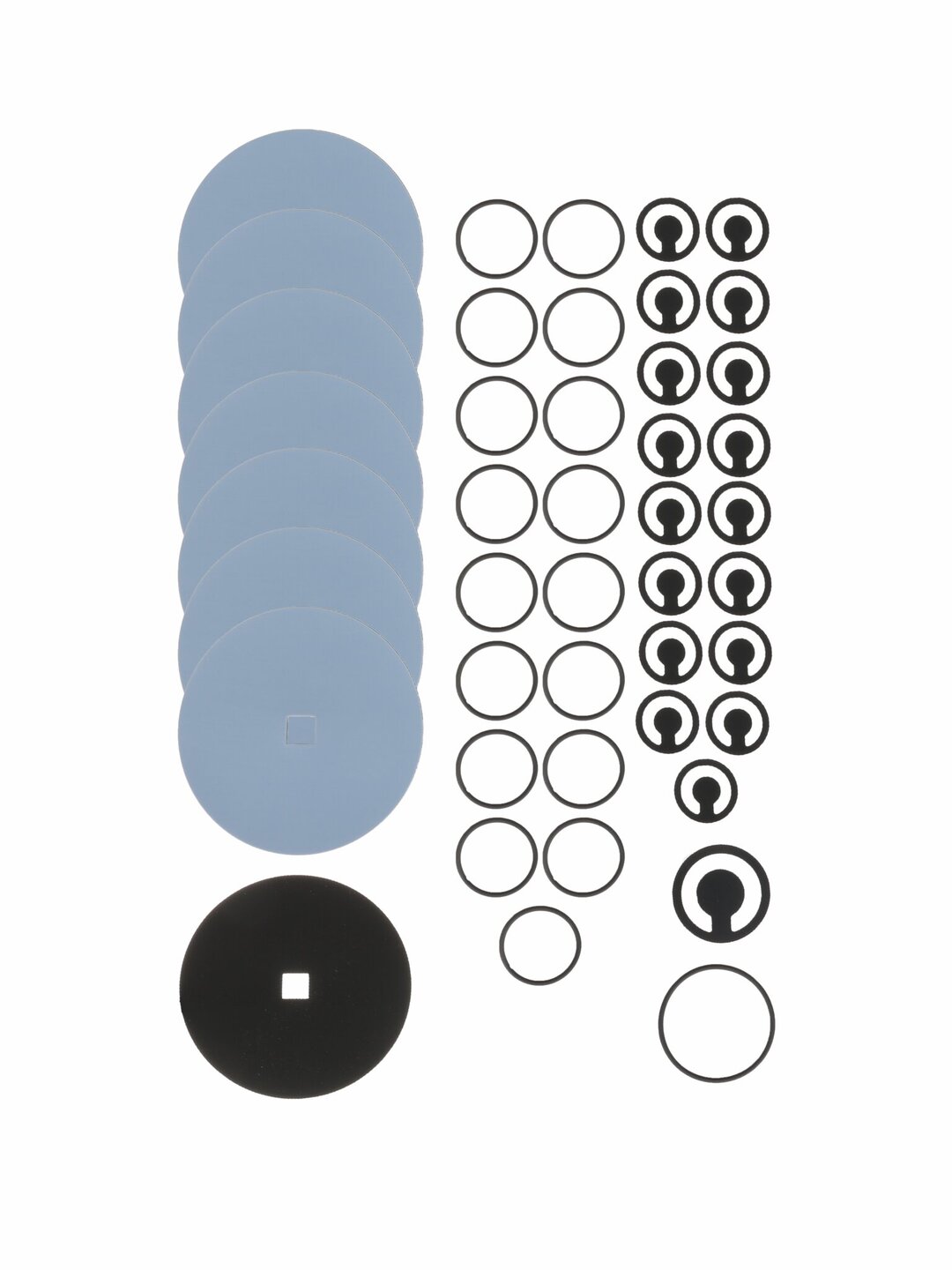

![Set of diaphragms and valvesfor MD 12C NT, MV 10C NT]() MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves

MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves- Complete kit

- Original spare parts

- Easy assembly

This might also interest you

-

![PC 3001 VARIO select VARIO® chemistry pumping unit]() PC 3001 VARIO select VARIO® chemistry pumping unit

PC 3001 VARIO select VARIO® chemistry pumping unit- Ultimate vacuum 2.0 mbar

- Pumping speed 2 m3/h

- Oilfree & chemically resistant

![Chemistry diaphragm pump MD 1C]() MD 1C Chemistry diaphragm pump

MD 1C Chemistry diaphragm pump- Ultimate vacuum 2 mbar

- Pumping speed 1.3 m3/h

- Oilfree & chemically resistant

![MD 4C NT Chemistry diaphragm pump]() MD 4C NT Chemistry diaphragm pump

MD 4C NT Chemistry diaphragm pump- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

![MD 4C VARIO select VARIO® chemistry diaphragm pump]() MD 4C VARIO select VARIO® chemistry diaphragm pump

MD 4C VARIO select VARIO® chemistry diaphragm pump- Ultimate vacuum 1.5 mbar

- Pumping speed 4.6 m3/h

- Oilfree & chemically resistant

![MD 4C NT +2AK Chemistry vacuum system]() MD 4C NT +2AK Chemistry vacuum system

MD 4C NT +2AK Chemistry vacuum system- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

![MD 4C NT +AK+EK Chemistry vacuum system]() MD 4C NT +AK+EK Chemistry vacuum system

MD 4C NT +AK+EK Chemistry vacuum system- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

Application examples

Oil-free vacuum for reactors and synthesis applicationsVacuum drying ovenChemistry vacuum system in action

These chemistry vacuum systems have a wide range of applications like evacuation, evaporation and pumping of gases and vapors. They provide particularly high pumping speed and are ideal for higher vacuum requirements, e.g., with high boiling solvents. The base MD 12C NT pump obtains a very good ultimate vacuum even with open gas ballast valve for condensate purge and delivers high pumping speed in a compact design. The pump design offers exceptionally high chemical resistance supporting almost universal usage in chemistry and pharmaceutics. The inlet separator (AK) retains particles and liquid droplets, the waste vapor condenser at the outlet (EK) is highly efficient and compact. The condenser enables near-100-percent solvent recovery, efficient recycling, and active protection of the environment.

Technical data and graphs

Max. pumping speed 50 Hz 12 m3/h Max. pumping speed 60 Hz 7.0 cfm Ultimate vacuum 2 mbar / 1.5 torr Ultimate vacuum with gas ballast 4 mbar / 3 torr Number of heads 8 Number of stages 3 Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Inlet connection Small flange KF DN 25 / hose nozzle DN 15 mm Outlet connection Hose nozzle DN 8-10 mm Coolant connection 2 x hose nozzle DN 6-8 mm Rated motor power 0.53 kW Rated motor speed at 50/60 Hz 1650 min-1 Protection class IEC 60529 IP 40 Dimension L in mm 616 mm Dimension B in mm 387 mm Dimension H in mm 395 mm Weight 28.9 kg Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) 50 dBA ATEX conformity II 3/- G Ex h IIC T3 Gc X Internal Atm. only NRTL certification No Items supplied Pumping unit completely mounted, ready for use, with manual. Rated mains voltage range 1 200-230 V Mains frequency 1 50-60 Hz  für Zoom klicken

für Zoom klicken

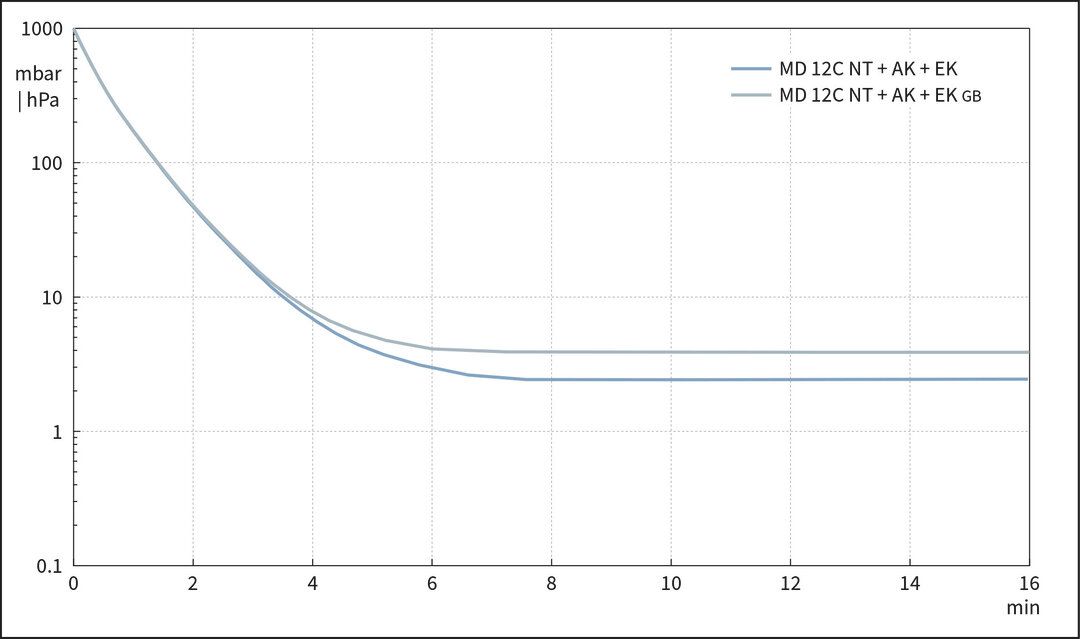

Pump down graph 50 Hz (100 l volume)

Downloads

MD 12C NT +AK+EK Chemistry vacuum systemMD 12C NT +AK+EKChemistry vacuum systemDownload Download Download Download DownloadTechnical data sheetData sheet PDF 4.1 MB 4.1 MB 4.1 MB 4.1 MB 4.1 MBEquipment

-

![Silencer with hose DN 8-10mm]() DN 8-10mm Silencer with hose 5cm

DN 8-10mm Silencer with hose 5cm![Clamping ring, aluminum, KF DN 20/25]() KF DN 20/25 Clamping ring for small flange

KF DN 20/25 Clamping ring for small flange- Quick link

- Nominal width KF DN 20/25

- Material Aluminum

![External centring ring, PBT,sealing ring FPM, KF DN 20/25]() KF DN 20/25 External centring ring for small flange

KF DN 20/25 External centring ring for small flange- Nominal width KF DN 20/25

- Material PBT

- Material sealing FKM

![PVC tubing with spiral, KF DN 25/1000 mm]() KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges

KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges- PVC with stainless steel spiral

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

![Small flange with hose nozzleKF DN 25/SW10, PP]() KF DN 25 / DN 10 mm Small flange with hose nozzle

KF DN 25 / DN 10 mm Small flange with hose nozzle- Hose shaft

- Nominal width KF DN 25

- Material PP

![Set of diaphragms and valvesfor MD 12C NT, MV 10C NT]() MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves

MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves- Complete kit

- Original spare parts

- Easy assembly

This might also interest you

-

![PC 3001 VARIO select VARIO® chemistry pumping unit]() PC 3001 VARIO select VARIO® chemistry pumping unit

PC 3001 VARIO select VARIO® chemistry pumping unit- Ultimate vacuum 2.0 mbar

- Pumping speed 2 m3/h

- Oilfree & chemically resistant

![Chemistry diaphragm pump MD 1C]() MD 1C Chemistry diaphragm pump

MD 1C Chemistry diaphragm pump- Ultimate vacuum 2 mbar

- Pumping speed 1.3 m3/h

- Oilfree & chemically resistant

![MD 4C NT Chemistry diaphragm pump]() MD 4C NT Chemistry diaphragm pump

MD 4C NT Chemistry diaphragm pump- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

![MD 4C VARIO select VARIO® chemistry diaphragm pump]() MD 4C VARIO select VARIO® chemistry diaphragm pump

MD 4C VARIO select VARIO® chemistry diaphragm pump- Ultimate vacuum 1.5 mbar

- Pumping speed 4.6 m3/h

- Oilfree & chemically resistant

![MD 4C NT +2AK Chemistry vacuum system]() MD 4C NT +2AK Chemistry vacuum system

MD 4C NT +2AK Chemistry vacuum system- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

![MD 4C NT +AK+EK Chemistry vacuum system]() MD 4C NT +AK+EK Chemistry vacuum system

MD 4C NT +AK+EK Chemistry vacuum system- Ultimate vacuum 1.5 mbar

- Pumping speed 3.4 m3/h

- Oilfree & chemically resistant

Application examples

Oil-free vacuum for reactors and synthesis applicationsVacuum drying oven