PC 3010 NT VARIOVARIO® chemistry diaphragm pump

Overview

- automatic optimization of the vacuum level throughout the process for high process reproducibility and unattended operation

- short process times due to zero-fluctuation (hysteresis-free) vacuum control, even for large amounts of vapor

- removable CVC 3000 vacuum controller, can be arranged flexibly, easily operated with clear text menus

- extraordinary diaphragm life for minimum operational and servicing costs

- PC 3010 NT VARIO: excellent environmental friendliness due to efficient solvent recovery

Ultimate vacuum

0.6 mbar

Ultimate vacuum with gas ballast

1.2 mbar

Max. pumping speed 50 Hz

12.8 m3/h

VARIO® chemistry diaphragm pump in action

These VARIO® pumps and pumping units feature a very high pumping speed and attain an outstanding ultimate vacuum. They are ideal for high vacuum requirements, e.g., for evaporation of most high boiling solvents even at low temperatures. They provide precise vacuum control by adjusting the diaphragm pump´s motor speed. The controller provides fully automatic evaporations without any need of parameter input. The pump design offers exceptionally high chemical resistance supporting almost universal usage in chemistry and pharmaceutics. The PC 3010 NT VARIO pumping unit relies on a well-proven operating concept for example for evaporation of large amounts of solvents. The inlet separator (AK) retains particles and liquid droplets, the waste vapor condenser at the outlet (EK) is highly efficient and compact. The condenser enables near-100-percent solvent recovery, efficient recycling, and active protection of the environment. For the MV 10C NT VARIO these accessories are optionally available and can be mounted later. The high pumping speed and the very good ultimate vacuum reduce the process time significantly, e.g., of evaporation of high boiling solvents. Typical applications are all drying and evaporation processes like in vacuum ovens, large rotary evaporators, at pilot plants, mini-plants or kilo laboratories. Evaporation processes can be run fully automatically with short process times and high sensitivity at the same time. The VARIO® control minimizes the danger of superheating and foaming and therefore ensures a constantly high process safety. With its inlet separator and efficient solvent recovery system, the PC 3010 NT VARIO is ideal for challenging operating conditions.

Technical data and graphs

| Max. pumping speed 50 Hz | 12.8 m3/h | |

| Max. pumping speed 60 Hz | 7.5 cfm | |

| Ultimate vacuum | 0.6 mbar / 0.45 torr | |

| Ultimate vacuum with gas ballast | 1.2 mbar / 0.9 torr | |

| Number of heads | 8 | |

| Number of stages | 4 | |

| Vacuum controller | CVC 3000 | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | Small flange KF DN 25 / hose nozzle DN 15 mm | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Coolant connection | 2 x hose nozzle DN 6-8 mm | |

| Rated motor power | 0.53 kW | |

| Protection class IEC 60529 | IP 40 | |

| Dimension L in mm | 616 mm | |

| Dimension B in mm | 387 mm | |

| Dimension H in mm | 420 mm | |

| Weight | 29.7 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 47 dBA | |

| NRTL certification | No | |

| Items supplied | Pumping unit completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 200-230 V | |

| Mains frequency 1 | 50-60 Hz |

Equipment

-

![Set of diaphragms and valvesfor MD 12C NT, MV 10C NT]() MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves

MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves- Complete kit

- Original spare parts

- Easy assembly

This might also interest you

-

![PC 3003 VARIO select VARIO® chemistry pumping unit]() PC 3003 VARIO select VARIO® chemistry pumping unit

PC 3003 VARIO select VARIO® chemistry pumping unit- Ultimate vacuum 0.6 mbar

- Pumping speed 2.8 m3/h

- Oilfree & chemically resistant

![MV 10C NT Chemistry diaphragm pump]() MV 10C NT Chemistry diaphragm pump

MV 10C NT Chemistry diaphragm pump- Ultimate vacuum 0.9 mbar

- Pumping speed 9.5 m3/h

- Oilfree & chemically resistant

![MV 10C NT +EK Chemistry vacuum system]() MV 10C NT +EK Chemistry vacuum system

MV 10C NT +EK Chemistry vacuum system- Ultimate vacuum 0.9 mbar

- Pumping speed 9.5 m3/h

- Oilfree & chemically resistant

VARIO® chemistry diaphragm pump in action

These VARIO® pumps and pumping units feature a very high pumping speed and attain an outstanding ultimate vacuum. They are ideal for high vacuum requirements, e.g., for evaporation of most high boiling solvents even at low temperatures. They provide precise vacuum control by adjusting the diaphragm pump´s motor speed. The controller provides fully automatic evaporations without any need of parameter input. The pump design offers exceptionally high chemical resistance supporting almost universal usage in chemistry and pharmaceutics. The PC 3010 NT VARIO pumping unit relies on a well-proven operating concept for example for evaporation of large amounts of solvents. The inlet separator (AK) retains particles and liquid droplets, the waste vapor condenser at the outlet (EK) is highly efficient and compact. The condenser enables near-100-percent solvent recovery, efficient recycling, and active protection of the environment. For the MV 10C NT VARIO these accessories are optionally available and can be mounted later. The high pumping speed and the very good ultimate vacuum reduce the process time significantly, e.g., of evaporation of high boiling solvents. Typical applications are all drying and evaporation processes like in vacuum ovens, large rotary evaporators, at pilot plants, mini-plants or kilo laboratories. Evaporation processes can be run fully automatically with short process times and high sensitivity at the same time. The VARIO® control minimizes the danger of superheating and foaming and therefore ensures a constantly high process safety. With its inlet separator and efficient solvent recovery system, the PC 3010 NT VARIO is ideal for challenging operating conditions.

Technical data and graphs

Max. pumping speed 50 Hz 12.8 m3/h Max. pumping speed 60 Hz 7.5 cfm Ultimate vacuum 0.6 mbar / 0.45 torr Ultimate vacuum with gas ballast 1.2 mbar / 0.9 torr Number of heads 8 Number of stages 4 Vacuum controller CVC 3000 Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Inlet connection Small flange KF DN 25 / hose nozzle DN 15 mm Outlet connection Hose nozzle DN 8-10 mm Coolant connection 2 x hose nozzle DN 6-8 mm Rated motor power 0.53 kW Protection class IEC 60529 IP 40 Dimension L in mm 616 mm Dimension B in mm 387 mm Dimension H in mm 420 mm Weight 29.7 kg Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) 47 dBA NRTL certification No Items supplied Pumping unit completely mounted, ready for use, with manual. Rated mains voltage range 1 200-230 V Mains frequency 1 50-60 Hz  für Zoom klicken

für Zoom klicken

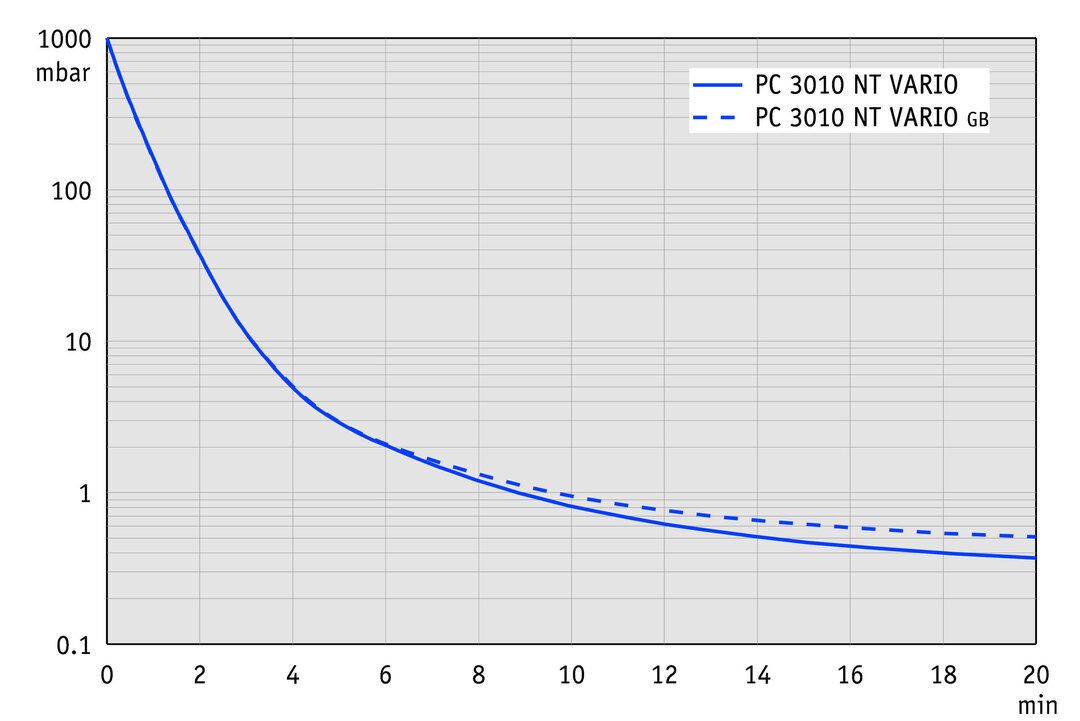

Pump down graph 50 Hz (100 l volume)

Equipment

-

![Set of diaphragms and valvesfor MD 12C NT, MV 10C NT]() MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves

MD 12C NT / MV 10C NT / PC 3012 NT / PC 3010 NT (also VARIO) Set of diaphragms and valves- Complete kit

- Original spare parts

- Easy assembly

This might also interest you

-

![PC 3003 VARIO select VARIO® chemistry pumping unit]() PC 3003 VARIO select VARIO® chemistry pumping unit

PC 3003 VARIO select VARIO® chemistry pumping unit- Ultimate vacuum 0.6 mbar

- Pumping speed 2.8 m3/h

- Oilfree & chemically resistant

![MV 10C NT Chemistry diaphragm pump]() MV 10C NT Chemistry diaphragm pump

MV 10C NT Chemistry diaphragm pump- Ultimate vacuum 0.9 mbar

- Pumping speed 9.5 m3/h

- Oilfree & chemically resistant

![MV 10C NT +EK Chemistry vacuum system]() MV 10C NT +EK Chemistry vacuum system

MV 10C NT +EK Chemistry vacuum system- Ultimate vacuum 0.9 mbar

- Pumping speed 9.5 m3/h

- Oilfree & chemically resistant