VACUU·PURE 10CScrew pump

Overview

- 10-3 mbar vacuum range

- 100% oil-free

- Chemically resistant

- No wear parts

Ultimate vacuum

5 x 10-3 mbar

Max. pumping speed 50 Hz

9 m3/h

Screw pump in action

The dry screw pump VACUU·PURE® 10C reliably delivers the benefits of oil-free vacuum technology in the pressure range of 10-3 mbar. The new vacuum pump combines three important benefits for the user: 100% oil-free, chemically resistant, and no wear parts. VACUU·PURE 10C is ideally suited for clean processes and the production of pure products. The screw pump is especially designed for processes in the vacuum range down to 10-3 mbar, however unlike other fine vacuum technologies it can be used across the entire pressure range from atmospheric pressure to its ultimate vacuum. At the same time, aggressive gases and vapors can be pumped without any worries because of the high chemical resistance. The use of a cold trap is no longer necessary in the majority of applications. VACUU·PURE easily handles high vapor loads through its extraordinary condensate compatibility. Thanks to this capability, a gas ballast is unnecessary, avoiding associated disadvantages like the reduction in pumping speed and an increase in noise levels. The integrated regeneration mode enables rapid drying of the pump at the end of the process. This allows sample throughput to be increased significantly as compared to other pump technologies.

Technical data and graphs

| Max. pumping speed 50 Hz | 9 m3/h | |

| Ultimate vacuum | 5 x 10-3 mbar / 3.8 x 10-3 torr (at 1013 mbar ambient pressure) | |

| Vacuum controller | without controller | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 15 mbar above atmospheric pressure bar | |

| Inlet connection | small flange KF DN 25 | |

| Outlet connection | small flange KF DN 25 | |

| Rated motor power | 0.7 kW | |

| Protection class IEC 60529 | IP 20 | |

| Dimension L in mm | 507 mm | |

| Dimension B in mm | 269 mm | |

| Dimension H in mm | 413 mm | |

| Weight | 21.5 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 52 dBA | |

| NRTL certification | Yes | |

| Items supplied | Pump completely mounted, ready for use, connection with small flange KF DN 25 (2x centering and clamping rings included), with manual. To establish a hose nozzle connection, suitable KF flanges with hose nozzle are available for order. | |

| Rated mains voltage range 1 | 100-230 V | |

| Mains frequency 1 | 50-60 Hz | |

| Interface | VACUU·BUS: Modbus RTU |

Downloads

Equipment

-

![Set AK + elbow for VACUU∙PURE 10Cfor silencing at the outletwith condensate separator KF DN 25,elbow KF DN 25/SLW 19, exhaust hose ID 19 (3m)and hose clamp]() VACUU·PURE AK + Winkel Set AK + elbow for VACUU∙PURE 10C

VACUU·PURE AK + Winkel Set AK + elbow for VACUU∙PURE 10C![Inlet separator AK with round bottom flask 500 ml,with KF DN 25, for VACUU·PURE]() AK 500 / KF DN 25 VACUU·PURE Inlet separator AK with round bottom flask 500 ml, with connections KF DN 25 and hose nozzle DN 15 mm, Leakage rate 5 x 10^-4 mbar l/s

AK 500 / KF DN 25 VACUU·PURE Inlet separator AK with round bottom flask 500 ml, with connections KF DN 25 and hose nozzle DN 15 mm, Leakage rate 5 x 10^-4 mbar l/s- Compact and leak-tight

- High conductance

- Easy draining of condensate

![Exhaust vapor condenser EK 600 withround bottom flask 500 ml, with KF DN 25,for VACUU·PURE]() EK 600 Base module for chemistry pumping unit (without pump)

EK 600 Base module for chemistry pumping unit (without pump)- For VACUU·PURE®

- Inlet small flange KF DN 25

- Outlet hose shaft DN 19 mm

![VACUU·PURE shuttle, mobile underframe for VACUU·PURE]() VACUU·PURE shuttle Mobile underframe

VACUU·PURE shuttle Mobile underframe- Mobile underframe

![PVC tubing with spiral, KF DN 25/1000 mm]() KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges

KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges- PVC with stainless steel spiral

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

![Small flange with hose nozzleKF DN 25/SW10, PP]() KF DN 25 / DN 10 mm Small flange with hose nozzle

KF DN 25 / DN 10 mm Small flange with hose nozzle- Hose shaft

- Nominal width KF DN 25

- Material PP

![Small flange with hose nozzleDN 25/SW15, PP]() KF DN 25 / DN 15 mm Small flange with hose nozzle

KF DN 25 / DN 15 mm Small flange with hose nozzle- Hose shaft

- Nominal width KF DN 25

- Material PP

![Elbow with small flange KF DN 25 andhose nozzle for tubing i.d. 19 mm, PP]() KF DN 25 / SLW 19 Elbow DN25/SLW19 for VACUU-PURE

KF DN 25 / SLW 19 Elbow DN25/SLW19 for VACUU-PURE![Digital I/O interface module VACUU·BUS,with 2 m VACUU·BUS cable]() VACUU·BUS® Digital-I/O-Module VACUU·BUS®

VACUU·BUS® Digital-I/O-Module VACUU·BUS®- Fault indicator from and to the CVC 3000

- Configurable as remote (Start/Stop) module

![Exhaust hose PVC, 26/19 mm (length in m)]() PVC, 26/19 mm, {179} mm Exhaust hose

PVC, 26/19 mm, {179} mm Exhaust hose- Sale per meter

- Material PVC

![Communication Kit, USB to VACUU·BUS converter forcommunication with VACUU·BUS devicesThis Communication kit may also be used to updateVACUU·PURE® software for VACUU·PURE® screw pumps.For more information, please send u]() VACUU·BUS® Communication Kit, USB to VACUU·BUS converter

VACUU·BUS® Communication Kit, USB to VACUU·BUS converter- Mains plug VACUU·BUS® / USB

- USB-VACUU·BUS converter

This might also interest you

Application examples

Fore vacuum for turbomolecular pumpsOil-free vacuum for reactors and synthesis applicationsSchlenk LineVacuum drying ovenFine vacuum distillationLyophilisation (freeze drying)Screw pump in action

The dry screw pump VACUU·PURE® 10C reliably delivers the benefits of oil-free vacuum technology in the pressure range of 10-3 mbar. The new vacuum pump combines three important benefits for the user: 100% oil-free, chemically resistant, and no wear parts. VACUU·PURE 10C is ideally suited for clean processes and the production of pure products. The screw pump is especially designed for processes in the vacuum range down to 10-3 mbar, however unlike other fine vacuum technologies it can be used across the entire pressure range from atmospheric pressure to its ultimate vacuum. At the same time, aggressive gases and vapors can be pumped without any worries because of the high chemical resistance. The use of a cold trap is no longer necessary in the majority of applications. VACUU·PURE easily handles high vapor loads through its extraordinary condensate compatibility. Thanks to this capability, a gas ballast is unnecessary, avoiding associated disadvantages like the reduction in pumping speed and an increase in noise levels. The integrated regeneration mode enables rapid drying of the pump at the end of the process. This allows sample throughput to be increased significantly as compared to other pump technologies.

Technical data and graphs

Max. pumping speed 50 Hz 9 m3/h Ultimate vacuum 5 x 10-3 mbar / 3.8 x 10-3 torr (at 1013 mbar ambient pressure) Vacuum controller without controller Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 15 mbar above atmospheric pressure bar Inlet connection small flange KF DN 25 Outlet connection small flange KF DN 25 Rated motor power 0.7 kW Protection class IEC 60529 IP 20 Dimension L in mm 507 mm Dimension B in mm 269 mm Dimension H in mm 413 mm Weight 21.5 kg Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) 52 dBA NRTL certification Yes Items supplied Pump completely mounted, ready for use, connection with small flange KF DN 25 (2x centering and clamping rings included), with manual. To establish a hose nozzle connection, suitable KF flanges with hose nozzle are available for order. Rated mains voltage range 1 100-230 V Mains frequency 1 50-60 Hz Interface VACUU·BUS: Modbus RTU  für Zoom klicken

für Zoom klicken

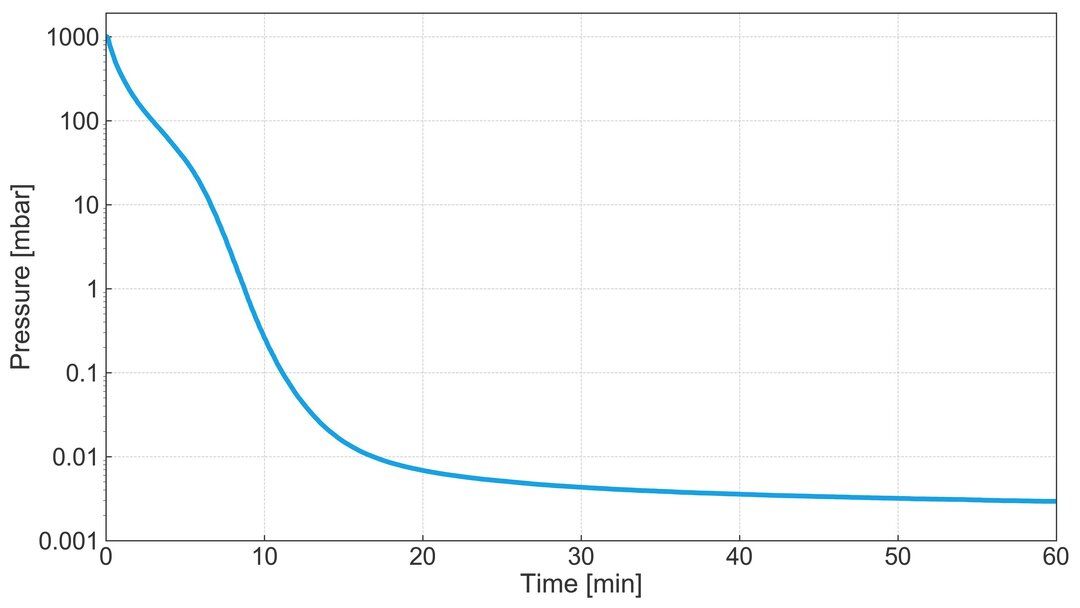

Pump down graph 50 Hz (100 l volume)

Downloads

Screw pump VACUU·PURE® 10C, chemically resistant,certification (NRTL): C/US,100-230 V, 50/60 Hz, CEE power cordVACUU·PURE 10CScrew pumpDownload Download Download Download DownloadTechnical data sheetData sheet PDF 2.6 MB 2.6 MB 2.6 MB 2.6 MB 2.7 MBEquipment

-

![Set AK + elbow for VACUU∙PURE 10Cfor silencing at the outletwith condensate separator KF DN 25,elbow KF DN 25/SLW 19, exhaust hose ID 19 (3m)and hose clamp]() VACUU·PURE AK + Winkel Set AK + elbow for VACUU∙PURE 10C

VACUU·PURE AK + Winkel Set AK + elbow for VACUU∙PURE 10C![Inlet separator AK with round bottom flask 500 ml,with KF DN 25, for VACUU·PURE]() AK 500 / KF DN 25 VACUU·PURE Inlet separator AK with round bottom flask 500 ml, with connections KF DN 25 and hose nozzle DN 15 mm, Leakage rate 5 x 10^-4 mbar l/s

AK 500 / KF DN 25 VACUU·PURE Inlet separator AK with round bottom flask 500 ml, with connections KF DN 25 and hose nozzle DN 15 mm, Leakage rate 5 x 10^-4 mbar l/s- Compact and leak-tight

- High conductance

- Easy draining of condensate

![Exhaust vapor condenser EK 600 withround bottom flask 500 ml, with KF DN 25,for VACUU·PURE]() EK 600 Base module for chemistry pumping unit (without pump)

EK 600 Base module for chemistry pumping unit (without pump)- For VACUU·PURE®

- Inlet small flange KF DN 25

- Outlet hose shaft DN 19 mm

![VACUU·PURE shuttle, mobile underframe for VACUU·PURE]() VACUU·PURE shuttle Mobile underframe

VACUU·PURE shuttle Mobile underframe- Mobile underframe

![PVC tubing with spiral, KF DN 25/1000 mm]() KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges

KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges- PVC with stainless steel spiral

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

![Small flange with hose nozzleKF DN 25/SW10, PP]() KF DN 25 / DN 10 mm Small flange with hose nozzle

KF DN 25 / DN 10 mm Small flange with hose nozzle- Hose shaft

- Nominal width KF DN 25

- Material PP

![Small flange with hose nozzleDN 25/SW15, PP]() KF DN 25 / DN 15 mm Small flange with hose nozzle

KF DN 25 / DN 15 mm Small flange with hose nozzle- Hose shaft

- Nominal width KF DN 25

- Material PP

![Elbow with small flange KF DN 25 andhose nozzle for tubing i.d. 19 mm, PP]() KF DN 25 / SLW 19 Elbow DN25/SLW19 for VACUU-PURE

KF DN 25 / SLW 19 Elbow DN25/SLW19 for VACUU-PURE![Digital I/O interface module VACUU·BUS,with 2 m VACUU·BUS cable]() VACUU·BUS® Digital-I/O-Module VACUU·BUS®

VACUU·BUS® Digital-I/O-Module VACUU·BUS®- Fault indicator from and to the CVC 3000

- Configurable as remote (Start/Stop) module

![Exhaust hose PVC, 26/19 mm (length in m)]() PVC, 26/19 mm, {179} mm Exhaust hose

PVC, 26/19 mm, {179} mm Exhaust hose- Sale per meter

- Material PVC

![Communication Kit, USB to VACUU·BUS converter forcommunication with VACUU·BUS devicesThis Communication kit may also be used to updateVACUU·PURE® software for VACUU·PURE® screw pumps.For more information, please send u]() VACUU·BUS® Communication Kit, USB to VACUU·BUS converter

VACUU·BUS® Communication Kit, USB to VACUU·BUS converter- Mains plug VACUU·BUS® / USB

- USB-VACUU·BUS converter

This might also interest you

Application examples

Fore vacuum for turbomolecular pumpsOil-free vacuum for reactors and synthesis applicationsSchlenk LineVacuum drying ovenFine vacuum distillationLyophilisation (freeze drying)