RZ 2.5Rotary vane pump

Overview

- high flow rates even at vacuum levels approaching ultimate vacuum

- very good ultimate vacuum even with gas ballast

- vacuum-tight at switch-off; external anti-suckback valve not needed

- large oil volume: Long intervals between oil changes

- ease of maintenance due to telescopic design

Ultimate vacuum

2 x 10-3 mbar

Ultimate vacuum with gas ballast

1 x 10-2 mbar

Max. pumping speed 50 Hz

2.3 m3/h

Rotary vane pump in action

The one-stage RE 2.5 and two-stage RZ 2.5 are high-performance rotary vane pumps with extra compact design and low weight. They are the ideal solution for a wide range of laboratory and process applications that require low ultimate vacuum at medium gas flow rate. The RZ 2.5 is also available combined with the oil mist filter (FO) and the VS 16 valve as a package.

Technical data and graphs

| Max. pumping speed 50 Hz | 2.3 m3/h | |

| Max. pumping speed 60 Hz | 1.65 cfm | |

| Ultimate partial vacuum (abs.) without gas ballast | 4 x 10-4 mbar | |

| Ultimate vacuum | 2 x 10-3 mbar / 1.5 x 10-3 torr | |

| Ultimate vacuum with gas ballast | 1 x 10-2 mbar / 0.75 x 10-2 torr | |

| Number of stages | 2 | |

| Lower ambient temperature (operation) | 12 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Oil capacity (B-Oil) min. | 0.36 l | |

| Oil capacity (B-Oil) max. | 0.84 l | |

| Inlet connection | small flange KF DN 16 | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Rated motor power | 0.1 kW | |

| Rated motor speed at 50/60 Hz | 1500/1800 min-1 | |

| Protection class IEC 60529 | IP 40 | |

| Dimension L in mm | 390 mm | |

| Dimension B in mm | 156 mm | |

| Dimension H in mm | 240 mm | |

| Weight | 14.2 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 48 dBA | |

| NRTL certification | No | |

| Items supplied | Pump oil filled and completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 230 V | |

| Mains frequency 1 | 50-60 Hz |

für Zoom klicken

für Zoom klicken

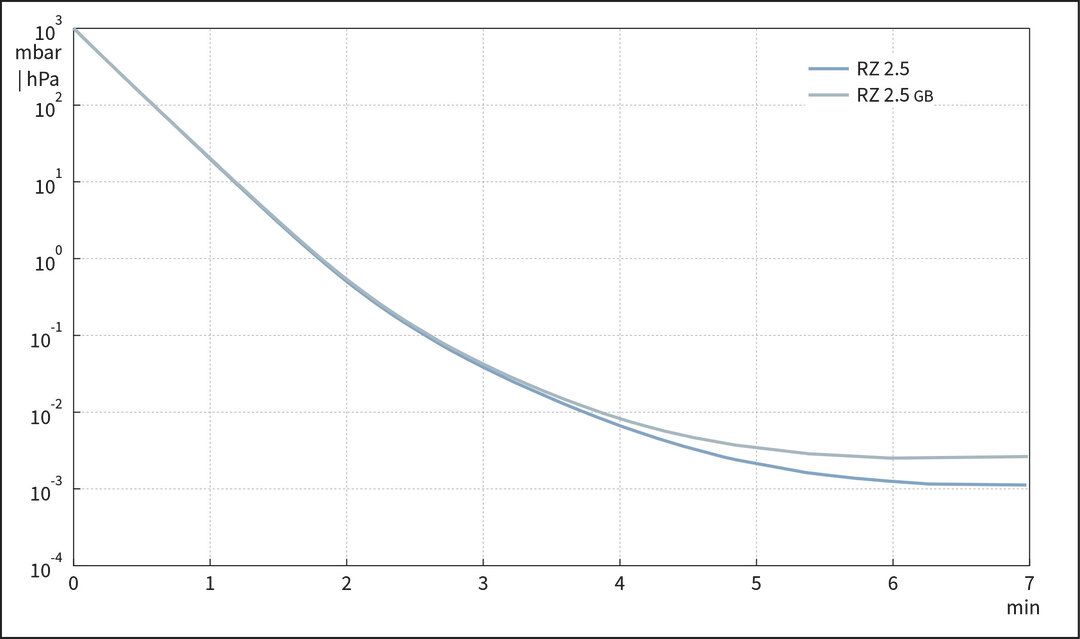

Pump down graph 50 Hz (10 l volume)

für Zoom klicken

für Zoom klicken

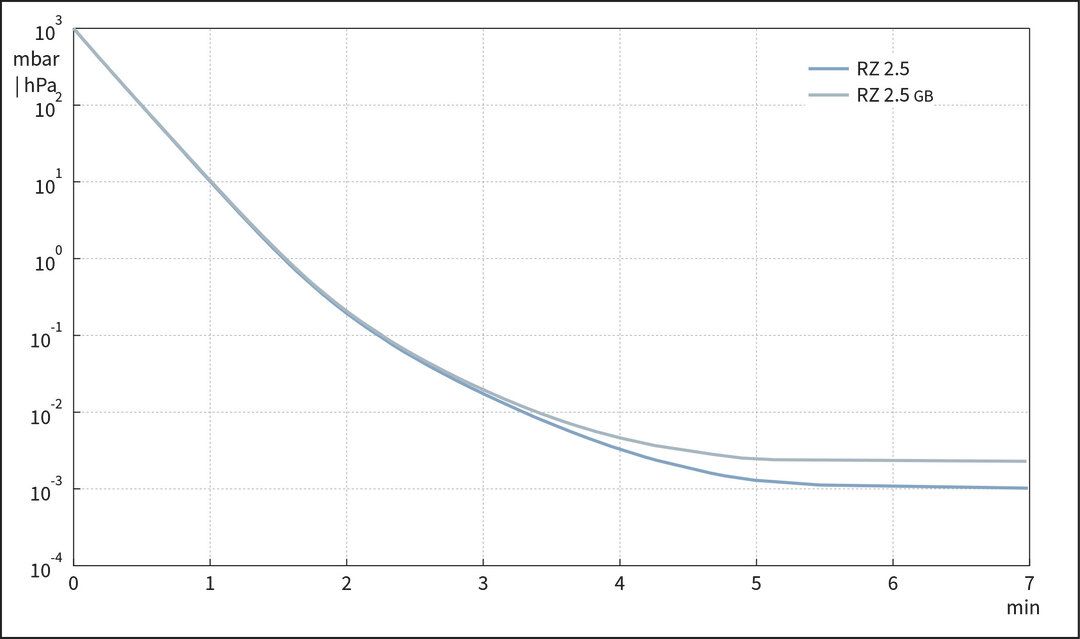

Pump down graph 60 Hz (10 l volume)

Downloads

Equipment

-

![Tubing, stainless steel, KF DN 16,length 1000 mm]() KF DN 16, 1000 mm Metal vacuum tubing with small flanges

KF DN 16, 1000 mm Metal vacuum tubing with small flanges- stainless steel

- Nominal width KF DN 16 mm | length 1000 mm

- Leak rate 1 x 10-9 mbar l/s

![Separator AK for RE/RZ 5 and RE/RZ 6 and RE/RZ 2.5]() AK for RE/RZ 5/6/2.5 Separator inlet side

AK for RE/RZ 5/6/2.5 Separator inlet side- Compact and leak-tight

- High conductance

- Easy draining of condensate

![Oil mist filter FO R 2 / 2.5 / 5 / 6]() FO R 2/2.5/5/6 Oil mist filter outlet side

FO R 2/2.5/5/6 Oil mist filter outlet side- Very high degree of separation

- Transparent catchpot

- Easy draining of oil

![VACUU·SELECT package for fine vacuum controlwith VACUU·VIEW extended for KF DN 16, within-line isolation valve VV-B 15C, T-piece,hose nozzle DN 10 and connecting parts DN 16,100-230V / 50-60Hz, plug CEE/CH/UK/US/AUS/CN]() VACUU·SELECT + VACUU·VIEW extended, KF DN 16 Package fine vacuum control

VACUU·SELECT + VACUU·VIEW extended, KF DN 16 Package fine vacuum control- Control down to 10-3 mbar.

- Automatic boiling point detection

- Predefined vacuum applications

![VACUU·SELECT package for fine vacuum controlwith Pirani sensor for KF DN 16, with in-lineisolation, valve VV-B 15C, T-piece,hose nozzle DN 10 and connecting parts DN 16,100-230V / 50-60Hz, plug CEE/CH/UK/US/AUS/CN]() VACUU·SELECT + VSP 3000, KF DN 16 Package fine vacuum control

VACUU·SELECT + VSP 3000, KF DN 16 Package fine vacuum control- Control down to 10-3 mbar.

- Automatic boiling point detection

- Predefined vacuum applications

![Vacuum tubing DN 8, transparent,price per meter]() DN 8 mm, sale per meter Vacuum tubing transparent

DN 8 mm, sale per meter Vacuum tubing transparent- Nominal width DN 8 mm

- Flexible

- Sale per meter

![Small flange with hose nozzleDN 16/DN 10, PP]()

This might also interest you

-

![Rotary vane pump package RZ 6 with oil mist filter and butterfly valve VS 16]() RZ 6 +FO +VS 16 Rotary vane pump

RZ 6 +FO +VS 16 Rotary vane pump- Ultimate vacuum 2 x 10-3 mbar

- Pumping speed 5.7 m3/h

- Vacuum-tight at switch-off

![Rotary vane pump package RZ 6, with oil mist filter, butterfly valve VS 16 and vacuum gauge VACUU·VIEW extended, 230 V/50-60 Hz]() RZ 6 +FO +VS 16 +VACUU·VIEW extended Rotary vane pump

RZ 6 +FO +VS 16 +VACUU·VIEW extended Rotary vane pump- Ultimate vacuum 2 x 10-3 mbar

- Pumping speed 5.7 m3/h

- Vacuum-tight at switch-off

![Rotary vane pump package RZ 6, with oil mist filter, butterfly valve VS 16 and vacuum gauge DCP 3000 +VSP 3000]() RZ 6 +FO +VS 16 +Set DCP+VSP 3000 Rotary vane pump

RZ 6 +FO +VS 16 +Set DCP+VSP 3000 Rotary vane pump- Ultimate vacuum 2 x 10-3 mbar

- Pumping speed 5.7 m3/h

- Vacuum-tight at switch-off

![Rotary vane pump package RZ 2.5 with oil mist filter and butterfly valve VS 16]() RZ 2.5 +FO +VS 16 Rotary vane pump

RZ 2.5 +FO +VS 16 Rotary vane pump- Ultimate vacuum 2 x 10-3 mbar

- Pumping speed 2.3 m3/h

- Vacuum-tight at switch-off

Application examples

Schlenk LineLyophilisation (freeze drying)Rotary vane pump in action

The one-stage RE 2.5 and two-stage RZ 2.5 are high-performance rotary vane pumps with extra compact design and low weight. They are the ideal solution for a wide range of laboratory and process applications that require low ultimate vacuum at medium gas flow rate. The RZ 2.5 is also available combined with the oil mist filter (FO) and the VS 16 valve as a package.

Technical data and graphs

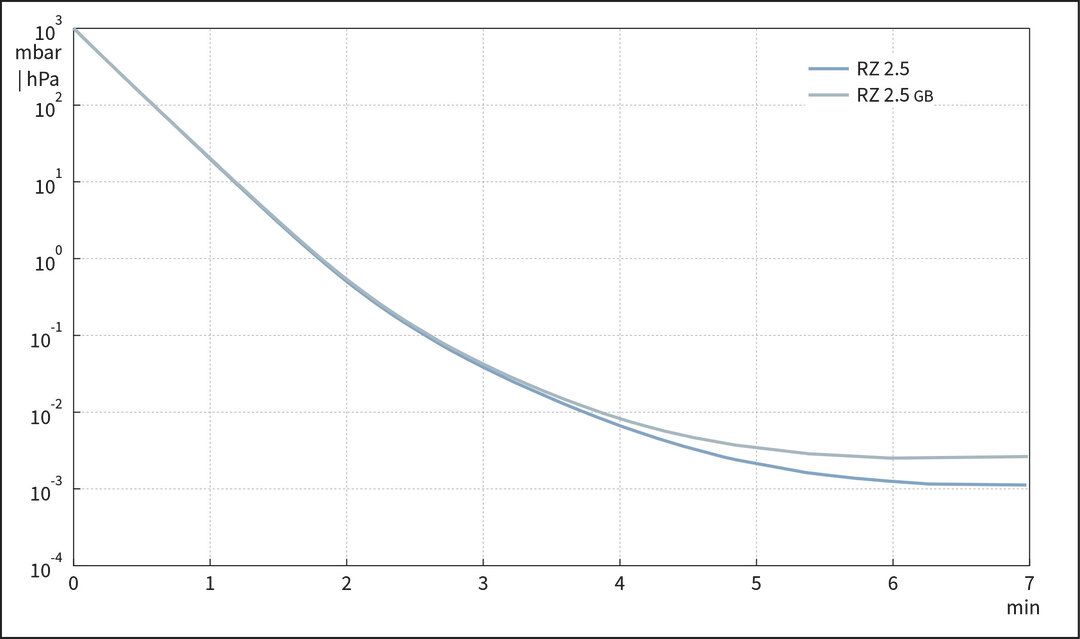

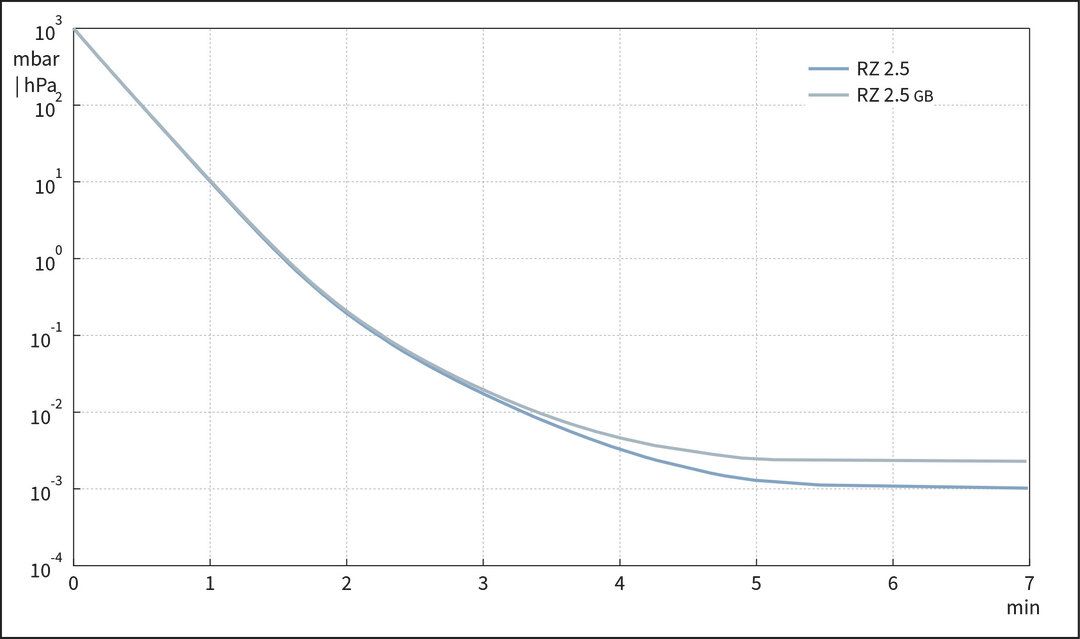

Max. pumping speed 50 Hz 2.3 m3/h Max. pumping speed 60 Hz 1.65 cfm Ultimate partial vacuum (abs.) without gas ballast 4 x 10-4 mbar Ultimate vacuum 2 x 10-3 mbar / 1.5 x 10-3 torr Ultimate vacuum with gas ballast 1 x 10-2 mbar / 0.75 x 10-2 torr Number of stages 2 Lower ambient temperature (operation) 12 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Oil capacity (B-Oil) min. 0.36 l Oil capacity (B-Oil) max. 0.84 l Inlet connection small flange KF DN 16 Outlet connection Hose nozzle DN 8-10 mm Rated motor power 0.1 kW Rated motor speed at 50/60 Hz 1500/1800 min-1 Protection class IEC 60529 IP 40 Dimension L in mm 390 mm Dimension B in mm 156 mm Dimension H in mm 240 mm Weight 14.2 kg Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) 48 dBA NRTL certification No Items supplied Pump oil filled and completely mounted, ready for use, with manual. Rated mains voltage range 1 230 V Mains frequency 1 50-60 Hz  für Zoom klicken

für Zoom klicken

Pump down graph 50 Hz (10 l volume)

für Zoom klicken

für Zoom klicken

Pump down graph 60 Hz (10 l volume)

Downloads

RZ 2.5 Rotary vane pumpRZ 2.5Rotary vane pumpDownload Download Download Download DownloadTechnical data sheetData sheet PDF 2.2 MB 2.2 MB 2.2 MB 2.2 MB 2.2 MBEquipment

-

![Tubing, stainless steel, KF DN 16,length 1000 mm]() KF DN 16, 1000 mm Metal vacuum tubing with small flanges

KF DN 16, 1000 mm Metal vacuum tubing with small flanges- stainless steel

- Nominal width KF DN 16 mm | length 1000 mm

- Leak rate 1 x 10-9 mbar l/s

![Separator AK for RE/RZ 5 and RE/RZ 6 and RE/RZ 2.5]() AK for RE/RZ 5/6/2.5 Separator inlet side

AK for RE/RZ 5/6/2.5 Separator inlet side- Compact and leak-tight

- High conductance

- Easy draining of condensate

![Oil mist filter FO R 2 / 2.5 / 5 / 6]() FO R 2/2.5/5/6 Oil mist filter outlet side

FO R 2/2.5/5/6 Oil mist filter outlet side- Very high degree of separation

- Transparent catchpot

- Easy draining of oil

![VACUU·SELECT package for fine vacuum controlwith VACUU·VIEW extended for KF DN 16, within-line isolation valve VV-B 15C, T-piece,hose nozzle DN 10 and connecting parts DN 16,100-230V / 50-60Hz, plug CEE/CH/UK/US/AUS/CN]() VACUU·SELECT + VACUU·VIEW extended, KF DN 16 Package fine vacuum control

VACUU·SELECT + VACUU·VIEW extended, KF DN 16 Package fine vacuum control- Control down to 10-3 mbar.

- Automatic boiling point detection

- Predefined vacuum applications

![VACUU·SELECT package for fine vacuum controlwith Pirani sensor for KF DN 16, with in-lineisolation, valve VV-B 15C, T-piece,hose nozzle DN 10 and connecting parts DN 16,100-230V / 50-60Hz, plug CEE/CH/UK/US/AUS/CN]() VACUU·SELECT + VSP 3000, KF DN 16 Package fine vacuum control

VACUU·SELECT + VSP 3000, KF DN 16 Package fine vacuum control- Control down to 10-3 mbar.

- Automatic boiling point detection

- Predefined vacuum applications

![Vacuum tubing DN 8, transparent,price per meter]() DN 8 mm, sale per meter Vacuum tubing transparent

DN 8 mm, sale per meter Vacuum tubing transparent- Nominal width DN 8 mm

- Flexible

- Sale per meter

![Small flange with hose nozzleDN 16/DN 10, PP]()

This might also interest you

-

![Rotary vane pump package RZ 6 with oil mist filter and butterfly valve VS 16]() RZ 6 +FO +VS 16 Rotary vane pump

RZ 6 +FO +VS 16 Rotary vane pump- Ultimate vacuum 2 x 10-3 mbar

- Pumping speed 5.7 m3/h

- Vacuum-tight at switch-off

![Rotary vane pump package RZ 6, with oil mist filter, butterfly valve VS 16 and vacuum gauge VACUU·VIEW extended, 230 V/50-60 Hz]() RZ 6 +FO +VS 16 +VACUU·VIEW extended Rotary vane pump

RZ 6 +FO +VS 16 +VACUU·VIEW extended Rotary vane pump- Ultimate vacuum 2 x 10-3 mbar

- Pumping speed 5.7 m3/h

- Vacuum-tight at switch-off

![Rotary vane pump package RZ 6, with oil mist filter, butterfly valve VS 16 and vacuum gauge DCP 3000 +VSP 3000]() RZ 6 +FO +VS 16 +Set DCP+VSP 3000 Rotary vane pump

RZ 6 +FO +VS 16 +Set DCP+VSP 3000 Rotary vane pump- Ultimate vacuum 2 x 10-3 mbar

- Pumping speed 5.7 m3/h

- Vacuum-tight at switch-off

![Rotary vane pump package RZ 2.5 with oil mist filter and butterfly valve VS 16]() RZ 2.5 +FO +VS 16 Rotary vane pump

RZ 2.5 +FO +VS 16 Rotary vane pump- Ultimate vacuum 2 x 10-3 mbar

- Pumping speed 2.3 m3/h

- Vacuum-tight at switch-off

Application examples

Schlenk LineLyophilisation (freeze drying)