MD 12 NTDiaphragm pump

Overview

- contamination-free pumping and evacuation

- high flow rate even near ultimate vacuum

- whisper quiet

- reduced process times

- exceptionally long diaphragm life and maintenance-free drive system for low lifetime costs

Ultimate vacuum

2 mbar

Max. pumping speed 50 Hz

12.1 m3/h

Diaphragm pump in action

The MD 12 NT diaphragm pump is an especially powerful pump for oil-free evacuation and pumping of non aggressive gases. The three-stage design of this eight-cylinder pump provides the advantageous combination of very high pumping speed and excellent ultimate vacuum. The flow path consists of aluminium, stainless steel and carefully selected plastics to permit a wide range of applications. The fabric-reinforced double diaphragms are made of highly flexible FKM for extended operating life and high vacuum performance. Eight-cylinder NT pumps feature quiet operation, with smooth and easy-to-clean surfaces. Like all VACUUBRAND diaphragm pumps they operate absolutely oil-free and do not have any sliding components in the gas path. In normal operation they are completely free of abrasion. This eliminates most of the particulate impurities frequently generated inside of scroll or piston pumps.

Technical data and graphs

| Max. pumping speed 50 Hz | 12.1 m3/h | |

| Max. pumping speed 60 Hz | 7.1 cfm | |

| Ultimate vacuum | 2 mbar / 1.5 torr | |

| Number of heads | 8 | |

| Number of stages | 3 | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | small flange KF DN 25 | |

| Outlet connection | G1/2" | |

| Rated motor power | 0.53 kW | |

| Rated motor speed at 50/60 Hz | 1650 min-1 | |

| Protection class IEC 60529 | IP 40 | |

| Dimension L in mm | 554 mm | |

| Dimension B in mm | 260 mm | |

| Dimension H in mm | 359 mm | |

| Weight | 30.2 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 50 dBA | |

| ATEX conformity | II 3/- G Ex h IIC T3 Gc X Internal Atm. only | |

| NRTL certification | No | |

| Items supplied | Pump completely mounted, ready for use, silencer, with manual. | |

| Rated mains voltage range 1 | 200-230 V | |

| Mains frequency 1 | 50-60 Hz |

Equipment

-

![Clamping ring, aluminum, KF DN 20/25]() KF DN 20/25 Clamping ring for small flange

KF DN 20/25 Clamping ring for small flange- Quick link

- Nominal width KF DN 20/25

- Material Aluminum

![External centring ring, PBT,sealing ring FPM, KF DN 20/25]() KF DN 20/25 External centring ring for small flange

KF DN 20/25 External centring ring for small flange- Nominal width KF DN 20/25

- Material PBT

- Material sealing FKM

![PVC tubing with spiral, KF DN 25/1000 mm]() KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges

KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges- PVC with stainless steel spiral

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

![Small flange with hose nozzleKF DN 25/SW10, PP]() KF DN 25 / DN 10 mm Small flange with hose nozzle

KF DN 25 / DN 10 mm Small flange with hose nozzle- Hose shaft

- Nominal width KF DN 25

- Material PP

![Set of diaphragms and valvesfor MV 10, MD 12]()

This might also interest you

-

![MD 4 NT Diaphragm pump]() MD 4 NT Diaphragm pump

MD 4 NT Diaphragm pump- Ultimate vacuum 1 mbar

- Pumping speed 3.8 m3/h

- Oilfree

![MD 1 Diaphragm pump]() MD 1 Diaphragm pump

MD 1 Diaphragm pump- Ultimate vacuum 1.5 mbar

- Pumping speed 1.2 m3/h

- Oilfree

![MD 4 VARIO select VARIO® diaphragm pump]()

Application examples

Fore vacuum for turbomolecular pumpsDiaphragm pump in action

The MD 12 NT diaphragm pump is an especially powerful pump for oil-free evacuation and pumping of non aggressive gases. The three-stage design of this eight-cylinder pump provides the advantageous combination of very high pumping speed and excellent ultimate vacuum. The flow path consists of aluminium, stainless steel and carefully selected plastics to permit a wide range of applications. The fabric-reinforced double diaphragms are made of highly flexible FKM for extended operating life and high vacuum performance. Eight-cylinder NT pumps feature quiet operation, with smooth and easy-to-clean surfaces. Like all VACUUBRAND diaphragm pumps they operate absolutely oil-free and do not have any sliding components in the gas path. In normal operation they are completely free of abrasion. This eliminates most of the particulate impurities frequently generated inside of scroll or piston pumps.

Technical data and graphs

Max. pumping speed 50 Hz 12.1 m3/h Max. pumping speed 60 Hz 7.1 cfm Ultimate vacuum 2 mbar / 1.5 torr Number of heads 8 Number of stages 3 Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Inlet connection small flange KF DN 25 Outlet connection G1/2" Rated motor power 0.53 kW Rated motor speed at 50/60 Hz 1650 min-1 Protection class IEC 60529 IP 40 Dimension L in mm 554 mm Dimension B in mm 260 mm Dimension H in mm 359 mm Weight 30.2 kg Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) 50 dBA ATEX conformity II 3/- G Ex h IIC T3 Gc X Internal Atm. only NRTL certification No Items supplied Pump completely mounted, ready for use, silencer, with manual. Rated mains voltage range 1 200-230 V Mains frequency 1 50-60 Hz  für Zoom klicken

für Zoom klicken

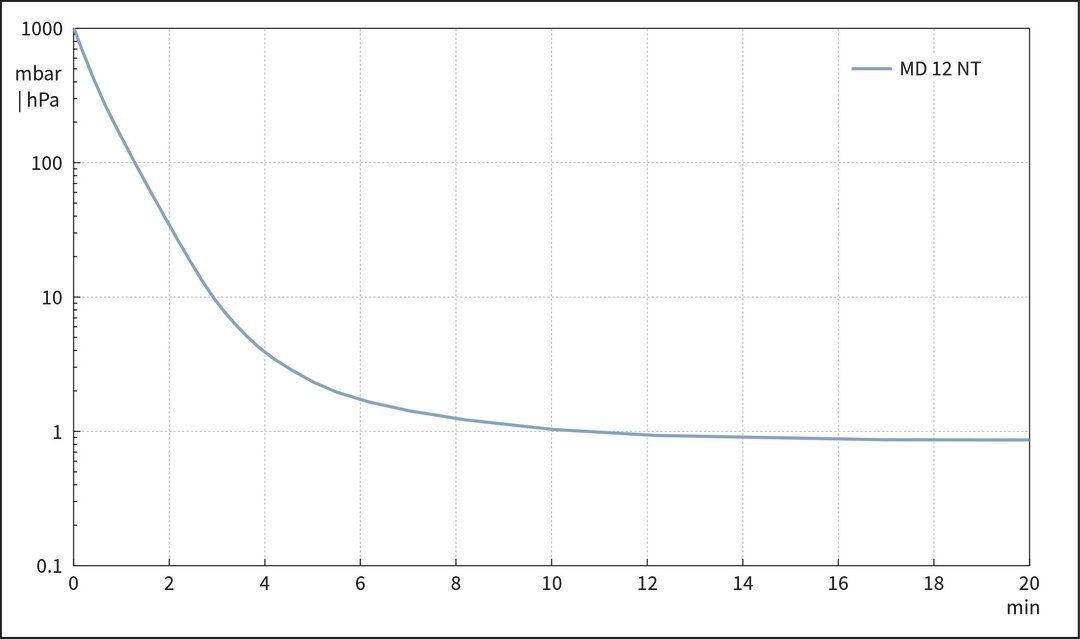

Pump down graph 50 Hz (100 l volume)

Equipment

-

![Clamping ring, aluminum, KF DN 20/25]() KF DN 20/25 Clamping ring for small flange

KF DN 20/25 Clamping ring for small flange- Quick link

- Nominal width KF DN 20/25

- Material Aluminum

![External centring ring, PBT,sealing ring FPM, KF DN 20/25]() KF DN 20/25 External centring ring for small flange

KF DN 20/25 External centring ring for small flange- Nominal width KF DN 20/25

- Material PBT

- Material sealing FKM

![PVC tubing with spiral, KF DN 25/1000 mm]() KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges

KF DN 25, 1000 mm Vacuum tubing PVC with internal stainless steel spiral, with small flanges- PVC with stainless steel spiral

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

![Small flange with hose nozzleKF DN 25/SW10, PP]() KF DN 25 / DN 10 mm Small flange with hose nozzle

KF DN 25 / DN 10 mm Small flange with hose nozzle- Hose shaft

- Nominal width KF DN 25

- Material PP

![Set of diaphragms and valvesfor MV 10, MD 12]()

This might also interest you

-

![MD 4 NT Diaphragm pump]() MD 4 NT Diaphragm pump

MD 4 NT Diaphragm pump- Ultimate vacuum 1 mbar

- Pumping speed 3.8 m3/h

- Oilfree

![MD 1 Diaphragm pump]() MD 1 Diaphragm pump

MD 1 Diaphragm pump- Ultimate vacuum 1.5 mbar

- Pumping speed 1.2 m3/h

- Oilfree

![MD 4 VARIO select VARIO® diaphragm pump]()

Application examples

Fore vacuum for turbomolecular pumps