VS 16CButterfly valve

Overview

- compact, economic design

- high conductance, low leakage rate

- gas-tight against atmosphere in both positions

- helium leak-tested

- easy to grip, lever-operated, with position indicator

Articleno.

20665007

Butterfly valve in action

In-line valve VS 16C, stainless steel, with small flange KF DN 16

The VS und VS C series valves are butterfly-type valves. A circular valve plate with a sealing ring on the circumference rotates around an axis at right angle to the valve axis. As a result, the valves leave virtually the entire cross section free, offering very good conductance. The valve bodies are made of one piece, machined from solid material, and require (in addition to the valve head seal) only one elastic shaft seal for rotational movement of the shaft. The valves provide low leakage and minimal degassing rate. The VS C series features a valve seal made of perfluorelastomer material (FFKM).Technical data and graphs

| Flange connection | small flange KF DN 16 | |

| Operation | Manual | |

| Leakage rate | 1 x 10-6 mbar l/s | |

| Fitting length between flanges | 65 mm |

This might also interest you

-

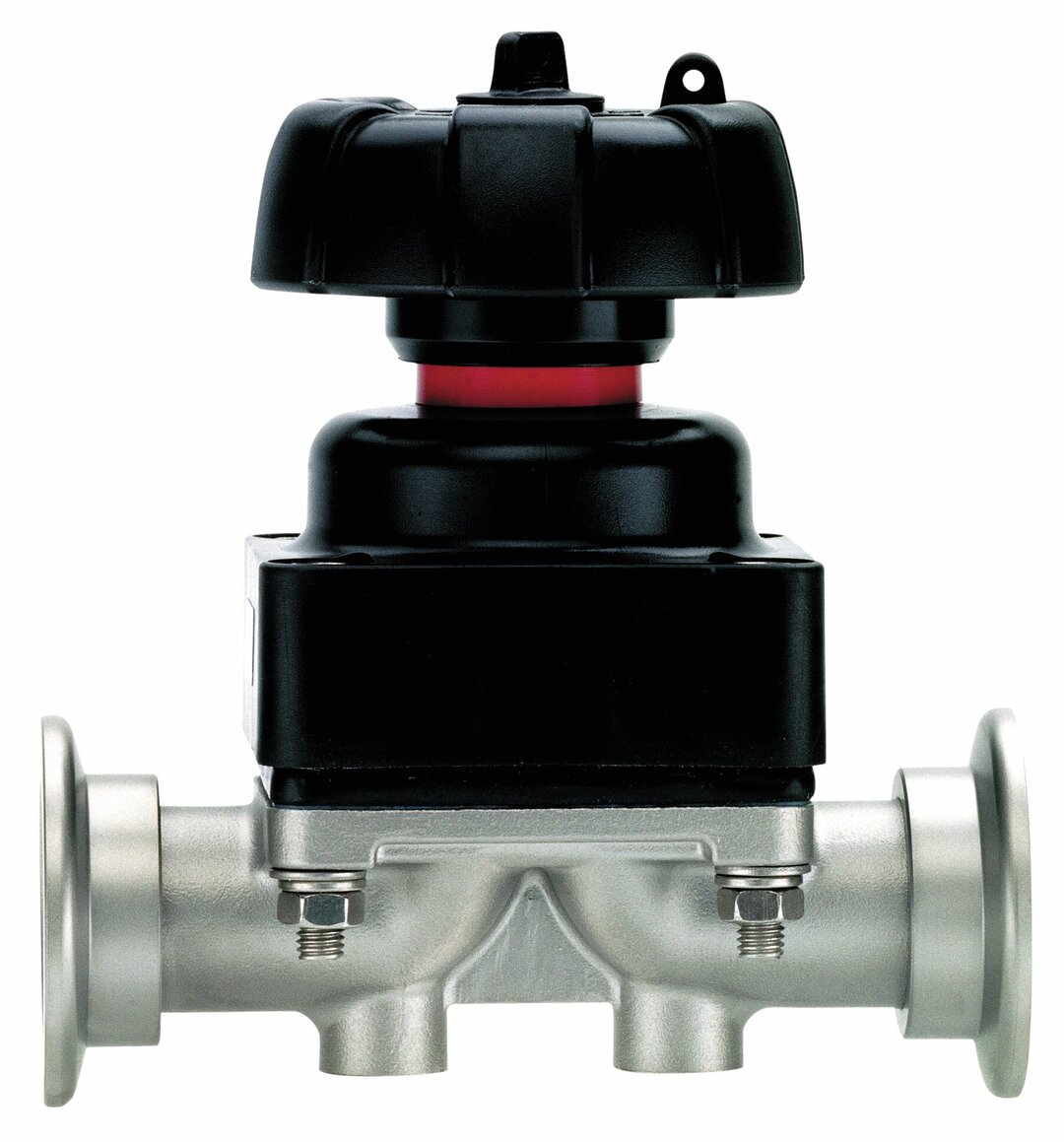

![Diaphragm in-line valve VM 25]() VM 25 Diaphragm valve

VM 25 Diaphragm valve- Chemically resistant

- Hand-operated

- Leak rate 1 x 10-4 mbar l/s

![Gas inlet valve VGL, stainless steel,with soldering connections]() VGL Gas inlet valve

VGL Gas inlet valve- Hand operated

- Fixed, permanent fitting

- Leak rate 1 x 10-9 min l/s

![Ball valve VK 16, brass, small flange,KF DN 16]() VK 16 Ball valve

VK 16 Ball valve- For rough and fine vacuum range

- Leak rate 1 x 10-6 min l/s

![Coolant valve VKW-B, VACUU·BUS,DN 1,5 mm, inlet G3/4" / G1/2",outlet nozzle 6 mm, cable length 2 mcertification (NRTL): C/US]() VKW-B Cooling water valve

VKW-B Cooling water valve- Mains plug VACUU·BUS®

- Nominal width 1.5 mm

![In-line isolation valve VV-B 6C,VACUU·BUS, PVDF/fluoroplastics,electromagnetic, with KF DN 16 andhose nozzle, certification (NRTL): C/US]() VV-B 6C Solenoid-operated valves

VV-B 6C Solenoid-operated valves- High operating cycles

- Long term tightness

- Leak rate 1 x 10-2 mbar l/s

![Bellow sealed angle valve VE,stainless steel, KF DN 16]() VE 16 WIG High vacuum bellow valve

VE 16 WIG High vacuum bellow valve- Excellent gas tightness

- Minimum degassing

- Leak rate 1 x 10-9 mbar l/s

![In-line valve VS 25, stainless steel,small flange, KF DN 25]() VS 25 Butterfly valve

VS 25 Butterfly valve- High conductance

- Minimal degassing rate

- Leak rate 1 x 10-6 mbar l/s

![Gas inlet valve VGS 10, stainless steel,small flange KF DN 10]()

Butterfly valve in action

In-line valve VS 16C, stainless steel, with small flange KF DN 16

The VS und VS C series valves are butterfly-type valves. A circular valve plate with a sealing ring on the circumference rotates around an axis at right angle to the valve axis. As a result, the valves leave virtually the entire cross section free, offering very good conductance. The valve bodies are made of one piece, machined from solid material, and require (in addition to the valve head seal) only one elastic shaft seal for rotational movement of the shaft. The valves provide low leakage and minimal degassing rate. The VS C series features a valve seal made of perfluorelastomer material (FFKM).

Technical data and graphs

Flange connection small flange KF DN 16 Operation Manual Leakage rate 1 x 10-6 mbar l/s Fitting length between flanges 65 mm