VE 16 WIGHigh vacuum bellow valve

Overview

- high conductance due to large stroke length

- excellent gas tightness, minimum degassing

- stainless steel version VE WIG bakeable to +150 °C

- simple dismantling and easy changing of seal

- dimensions of the VE valve are the same as elbow with corresponding nominal width

Articleno.

20674020

High vacuum bellow valve in action

Bellow sealed angle valve VE, stainless steel, KF DN 16

High vacuum, helium leak-tested right angle valves VE have stainless steel bellows which seals the drive mechanism without any gap on the vacuum side. Due to the screw-thread mechanism, these valves offer a certain control of conductance. They are mountable in any position because of their air tightness in both positions. The body is either made of solid aluminum or stainless steel (VE WIG). The stainless steel valves are tungsten inert gas welded from the inside for maximum gas tightness and minimum degassing rates.Technical data and graphs

| Flange connection | small flange KF DN 16 | |

| Operation | Manual | |

| Leakage rate | 1 x 10-9 mbar l/s | |

| Leakage rate of seat | 1 x 10-7 | |

| Fitting length between flanges | 40 mm |

This might also interest you

-

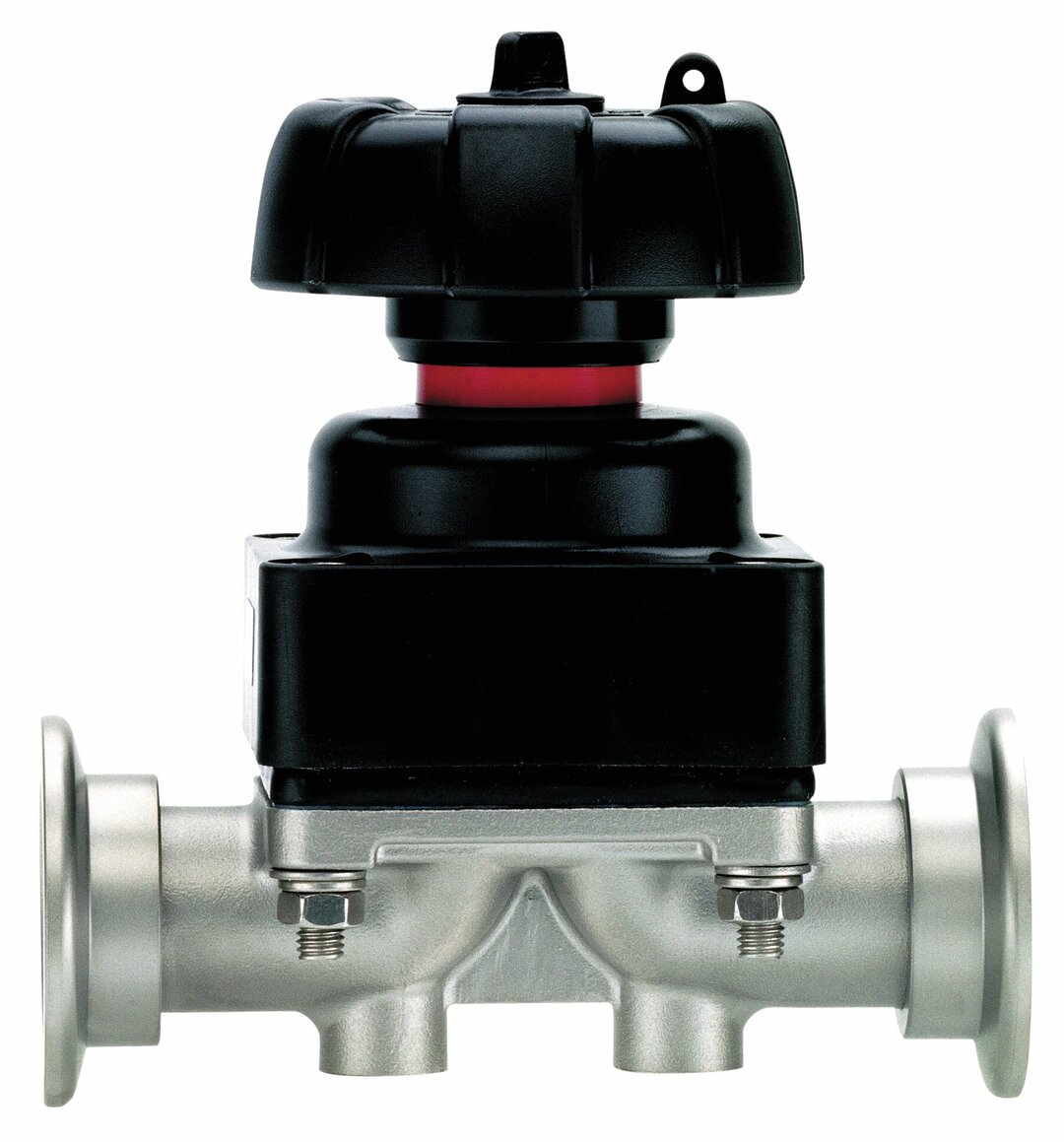

![Diaphragm in-line valve VM 25]() VM 25 Diaphragm valve

VM 25 Diaphragm valve- Chemically resistant

- Hand-operated

- Leak rate 1 x 10-4 mbar l/s

![Gas inlet valve VGL, stainless steel,with soldering connections]() VGL Gas inlet valve

VGL Gas inlet valve- Hand operated

- Fixed, permanent fitting

- Leak rate 1 x 10-9 min l/s

![Ball valve VK 16, brass, small flange,KF DN 16]() VK 16 Ball valve

VK 16 Ball valve- For rough and fine vacuum range

- Leak rate 1 x 10-6 min l/s

![Coolant valve VKW-B, VACUU·BUS,DN 1,5 mm, inlet G3/4" / G1/2",outlet nozzle 6 mm, cable length 2 mcertification (NRTL): C/US]() VKW-B Cooling water valve

VKW-B Cooling water valve- Mains plug VACUU·BUS®

- Nominal width 1.5 mm

![In-line isolation valve VV-B 6C,VACUU·BUS, PVDF/fluoroplastics,electromagnetic, with KF DN 16 andhose nozzle, certification (NRTL): C/US]() VV-B 6C Solenoid-operated valves

VV-B 6C Solenoid-operated valves- High operating cycles

- Long term tightness

- Leak rate 1 x 10-2 mbar l/s

![In-line valve VS 25, stainless steel,small flange, KF DN 25]() VS 25 Butterfly valve

VS 25 Butterfly valve- High conductance

- Minimal degassing rate

- Leak rate 1 x 10-6 mbar l/s

![Gas inlet valve VGS 10, stainless steel,small flange KF DN 10]()

High vacuum bellow valve in action

Bellow sealed angle valve VE, stainless steel, KF DN 16

High vacuum, helium leak-tested right angle valves VE have stainless steel bellows which seals the drive mechanism without any gap on the vacuum side. Due to the screw-thread mechanism, these valves offer a certain control of conductance. They are mountable in any position because of their air tightness in both positions. The body is either made of solid aluminum or stainless steel (VE WIG). The stainless steel valves are tungsten inert gas welded from the inside for maximum gas tightness and minimum degassing rates.

Technical data and graphs

Flange connection small flange KF DN 16 Operation Manual Leakage rate 1 x 10-9 mbar l/s Leakage rate of seat 1 x 10-7 Fitting length between flanges 40 mm