VV-B 6Solenoid-operated valves

Overview

- good chemical resistance

- significantly better long term tightness even after long operating time

- easy to clean

- versatile connection alternatives via small flange or hose nozzle

- low leakage rate

Articleno.

20674290

Solenoid-operated valves in action

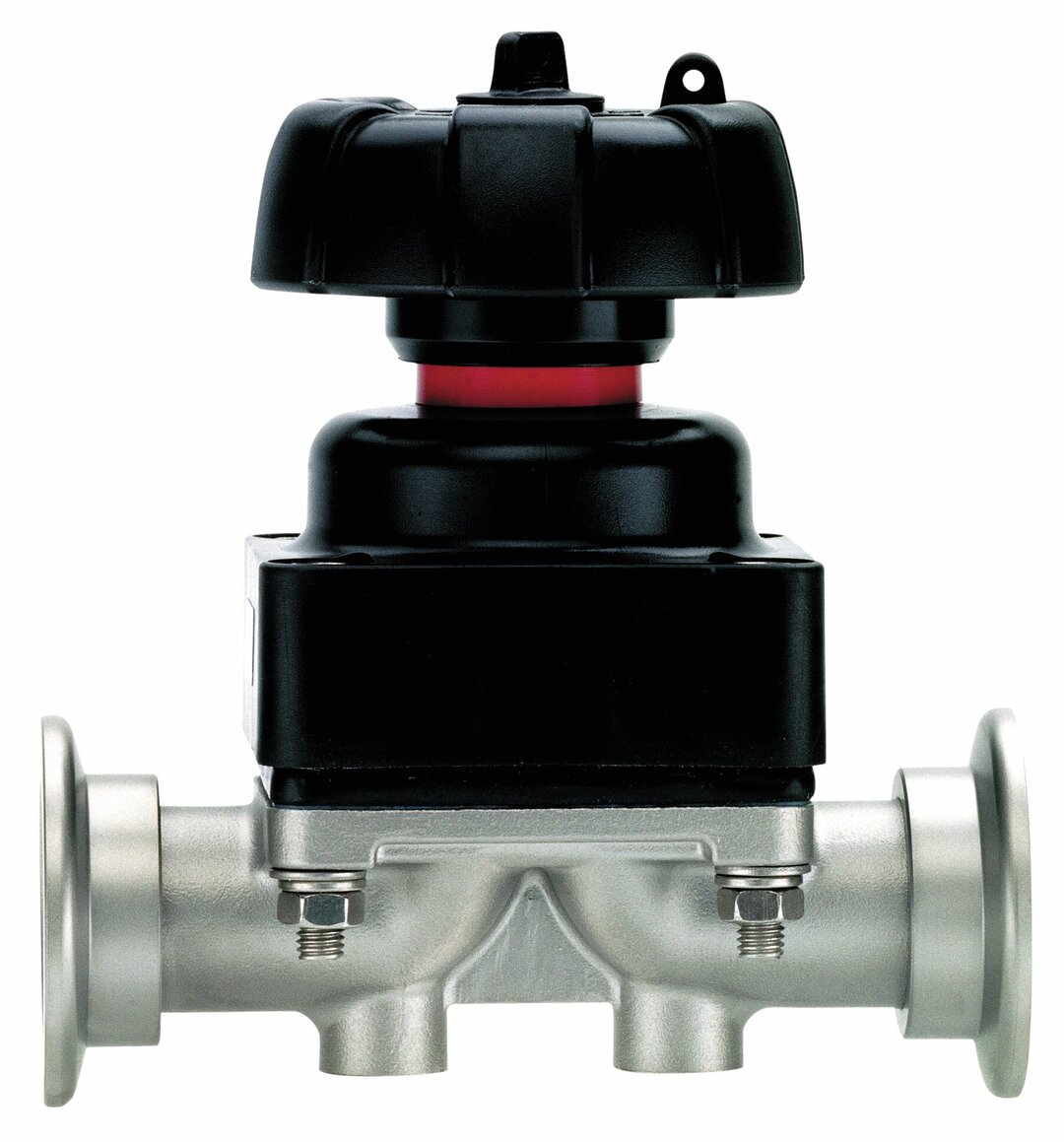

In-line isolation valve VV-B 6, VACUU· BUS, FPM/PP, electromagnetic, DN 16 certification (NRTL): C/US

These straight-through valves with electromagnetic (solenoid) drive are used for operating cycles with short intervals and, therefore, are often used as vacuum control valves. The straightforward design provides a valve with low leakage rate. The valves in version VV C are made of materials with excellent chemical resistance. The valve sealing of the VV-B 6C is made of a special fluoroelastomer with better form stability than common PTFE, much higher chemical resistance than FKM and excellent long-term leak tightness characteristics.Technical data and graphs

| Upper ambient temperature (operation) | 50 °C | |

| Lower ambient temperature (operation) | 0 °C | |

| Max. gas temperature | 80 °C | |

| Flange connection | Small flange KF DN 16 or hose nozzle DN 6/10 mm | |

| Operation | VACUU·BUS® | |

| Leakage rate | 1 x 10-5 mbar l/s | |

| Max. switching frequency | 120 pro Min. | |

| Fitting length between flanges | 100 mm |

This might also interest you

-

![Diaphragm in-line valve VM 25]() VM 25 Diaphragm valve

VM 25 Diaphragm valve- Chemically resistant

- Hand-operated

- Leak rate 1 x 10-4 mbar l/s

![Gas inlet valve VGL, stainless steel,with soldering connections]() VGL Gas inlet valve

VGL Gas inlet valve- Hand operated

- Fixed, permanent fitting

- Leak rate 1 x 10-9 min l/s

![Ball valve VK 16, brass, small flange,KF DN 16]() VK 16 Ball valve

VK 16 Ball valve- For rough and fine vacuum range

- Leak rate 1 x 10-6 min l/s

![Coolant valve VKW-B, VACUU·BUS,DN 1,5 mm, inlet G3/4" / G1/2",outlet nozzle 6 mm, cable length 2 mcertification (NRTL): C/US]() VKW-B Cooling water valve

VKW-B Cooling water valve- Mains plug VACUU·BUS®

- Nominal width 1.5 mm

![In-line isolation valve VV-B 6C,VACUU·BUS, PVDF/fluoroplastics,electromagnetic, with KF DN 16 andhose nozzle, certification (NRTL): C/US]() VV-B 6C Solenoid-operated valves

VV-B 6C Solenoid-operated valves- High operating cycles

- Long term tightness

- Leak rate 1 x 10-2 mbar l/s

![Bellow sealed angle valve VE,stainless steel, KF DN 16]() VE 16 WIG High vacuum bellow valve

VE 16 WIG High vacuum bellow valve- Excellent gas tightness

- Minimum degassing

- Leak rate 1 x 10-9 mbar l/s

![In-line valve VS 25, stainless steel,small flange, KF DN 25]() VS 25 Butterfly valve

VS 25 Butterfly valve- High conductance

- Minimal degassing rate

- Leak rate 1 x 10-6 mbar l/s

![Gas inlet valve VGS 10, stainless steel,small flange KF DN 10]()

Solenoid-operated valves in action

In-line isolation valve VV-B 6, VACUU· BUS, FPM/PP, electromagnetic, DN 16 certification (NRTL): C/US

These straight-through valves with electromagnetic (solenoid) drive are used for operating cycles with short intervals and, therefore, are often used as vacuum control valves. The straightforward design provides a valve with low leakage rate. The valves in version VV C are made of materials with excellent chemical resistance. The valve sealing of the VV-B 6C is made of a special fluoroelastomer with better form stability than common PTFE, much higher chemical resistance than FKM and excellent long-term leak tightness characteristics.

Technical data and graphs

Upper ambient temperature (operation) 50 °C Lower ambient temperature (operation) 0 °C Max. gas temperature 80 °C Flange connection Small flange KF DN 16 or hose nozzle DN 6/10 mm Operation VACUU·BUS® Leakage rate 1 x 10-5 mbar l/s Max. switching frequency 120 pro Min. Fitting length between flanges 100 mm