MD 4C EX +AK+EKChemistry vacuum system

Overview

- outstanding chemical resistance and superior vapor tolerance

- flame proof motor with integrated, self-locking overload and excess temperature protection for direct 230V / 50Hz single phase power supply. No need for any additional and specific overcurrent protection device

- overpressure safety relief valves internally and at outlet

- safety diaphragm technology with option for inert gas purge and detection of diaphragm breakage

- separator AK and emission condenser EK for pump protection and solvent recovery

Ultimate vacuum

3 mbar

Ultimate vacuum with gas ballast

10 mbar

Max. pumping speed 50 Hz

3.7 m3/h

Chemistry vacuum system in action

ATEX chemistry vacuum systems are ready for use for applications with large amounts of condensable vapors due to optimally configured accessories. Typical applications are rotary evaporators and drying ovens with potentially explosive atmospheres. The separator at the inlet (AK) retains particles and liquid droplets. The waste vapor condenser at the outlet (EK) is highly efficient and compact. The condenser enables near-100-percent solvent recovery. Included in delivery is a separate gas ballast connection part for use with inert gas.

Technical data and graphs

| Max. pumping speed 50 Hz | 3.7 m3/h | |

| Ultimate vacuum | 3 mbar / 2.3 torr | |

| Ultimate vacuum with gas ballast | 10 mbar / 7.5 torr | |

| Number of heads | 4 | |

| Number of stages | 3 | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | small flange KF DN 25 | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Coolant connection | 2 x hose nozzle DN 6-8 mm | |

| Rated motor power | 0.25 kW | |

| Rated motor speed at 50/60 Hz | 1500 min-1 | |

| Protection class IEC 60529 | IP 54 | |

| Dimension L in mm | 600 mm | |

| Dimension B in mm | 365 mm | |

| Dimension H in mm | 420 mm | |

| Weight | 37.4 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 53 dBA | |

| ATEX conformity | Pumping chamber (pumped gases): II 2G Ex h IIC T3 Gb X, Environment with inert purge gas: II 2G Ex h IIB T4 Gb X, Environment without inert purge gas: II 3G Ex h IIB T4 Gc X, Motor: II 2G Ex db IIB T4 Gb | |

| NRTL certification | No | |

| Items supplied | Pumping unit completely mounted with inlet separator and emission condenser, with manual, 10 m cable without plug. Shatter and shock protection for glass parts are to be provided by the customer. | |

| Rated mains voltage range 1 | 230 V | |

| Mains frequency 1 | 50 Hz |

Downloads

Equipment

-

![PTFE tubing antistatic, KF DN 25/1000 mm]() KF DN 25, 1000 mm PTFE-tubing (antistatic) with small flanges

KF DN 25, 1000 mm PTFE-tubing (antistatic) with small flanges- PTFE (antistatic) / stainless steel

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

This might also interest you

-

![Chemistry diaphragm pump MZ 2C EXtwo stage, 230 V / 50 Hzwith ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment (with inert pur]() MZ 2C EX Chemistry diaphragm pump

MZ 2C EX Chemistry diaphragm pump- Ultimate vacuum 12 mbar

- ATEX conformity

- Oilfree & chemically resistant

![Chemistry vacuum system MZ 2C EX + AK+EKtwo stage, 230 V / 50 Hzwith ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment (with in]() MZ 2C EX +AK+EK Chemistry vacuum system

MZ 2C EX +AK+EK Chemistry vacuum system- Ultimate vacuum 12 mbar

- ATEX conformity

- Oilfree & chemically resistant

![ATEX diaphragm pump MD 4C EX]() MD 4C EX Chemistry diaphragm pump

MD 4C EX Chemistry diaphragm pump- Ultimate vacuum 3 mbar

- ATEX conformity

- Oilfree & chemically resistant

![Chemistry diaphragm pump MD 4C EX VARIOthree stage, 230 V / 50 Hzwith ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment (with i]() MD 4C EX VARIO VARIO® chemistry diaphragm pump

MD 4C EX VARIO VARIO® chemistry diaphragm pump- Ultimate vacuum 3 mbar

- ATEX conformity

- Oilfree & chemically resistant

![Chemistry pumping unitMD 4C EX VARIO +AK+EK,three stage, 230 V / 50 Hz,with ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment]() MD 4C EX VARIO +AK+EK VARIO® chemistry vacuum system

MD 4C EX VARIO +AK+EK VARIO® chemistry vacuum system- Ultimate vacuum 3 mbar

- ATEX conformity

- Oilfree & chemically resistant

![Chemistry diaphragm pump MV 10C EX VARIOfour stage, 230 V / 50 Hzwith ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment (with i]() MV 10C EX VARIO Chemistry diaphragm pump

MV 10C EX VARIO Chemistry diaphragm pump- Ultimate vacuum 2 mbar

- ATEX conformity

- Oilfree & chemically resistant

![Chemistry pumping unitMV 10C EX VARIO +AK+EK,four stage, 230 V / 50 Hzwith ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment]() MV 10C EX VARIO +AK+EK VARIO® chemistry diaphragm pump

MV 10C EX VARIO +AK+EK VARIO® chemistry diaphragm pump- Ultimate vacuum 2 mbar

- ATEX conformity

- Oilfree & chemically resistant

Chemistry vacuum system in action

ATEX chemistry vacuum systems are ready for use for applications with large amounts of condensable vapors due to optimally configured accessories. Typical applications are rotary evaporators and drying ovens with potentially explosive atmospheres. The separator at the inlet (AK) retains particles and liquid droplets. The waste vapor condenser at the outlet (EK) is highly efficient and compact. The condenser enables near-100-percent solvent recovery. Included in delivery is a separate gas ballast connection part for use with inert gas.

Technical data and graphs

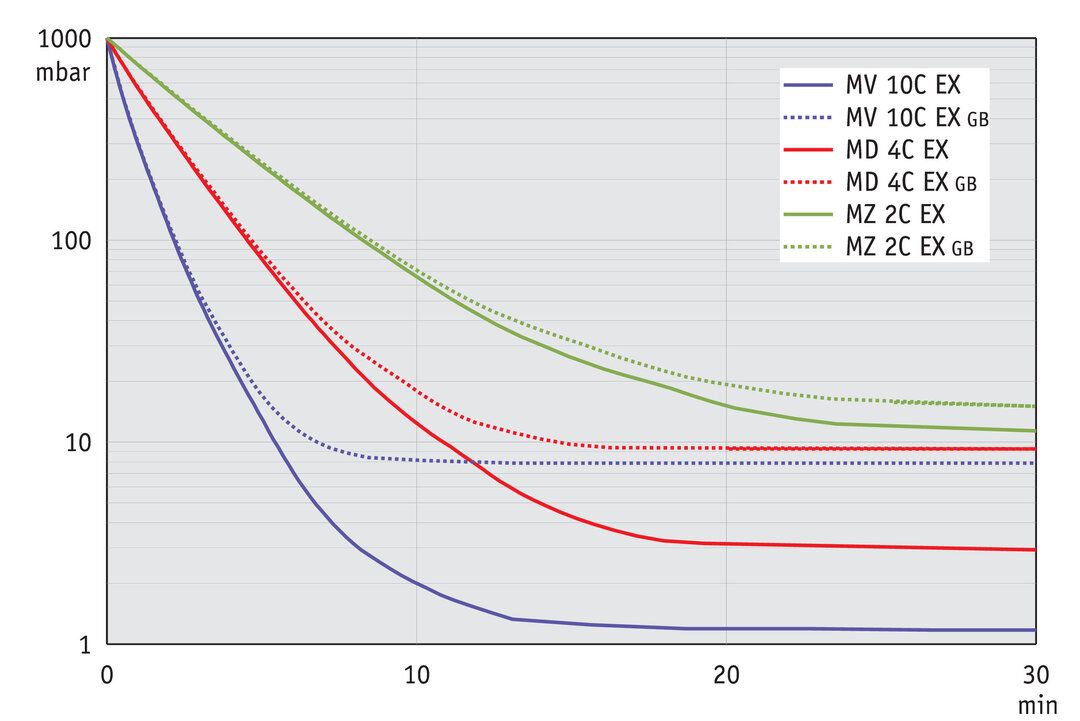

Max. pumping speed 50 Hz 3.7 m3/h Ultimate vacuum 3 mbar / 2.3 torr Ultimate vacuum with gas ballast 10 mbar / 7.5 torr Number of heads 4 Number of stages 3 Lower ambient temperature (operation) 10 °C Upper ambient temperature (operation) 40 °C Lower ambient temperature (storage) -10 °C Upper ambient temperature (storage) 60 °C Max. back pressure (abs.) 1.1 bar Inlet connection small flange KF DN 25 Outlet connection Hose nozzle DN 8-10 mm Coolant connection 2 x hose nozzle DN 6-8 mm Rated motor power 0.25 kW Rated motor speed at 50/60 Hz 1500 min-1 Protection class IEC 60529 IP 54 Dimension L in mm 600 mm Dimension B in mm 365 mm Dimension H in mm 420 mm Weight 37.4 kg Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) 53 dBA ATEX conformity Pumping chamber (pumped gases): II 2G Ex h IIC T3 Gb X, Environment with inert purge gas: II 2G Ex h IIB T4 Gb X, Environment without inert purge gas: II 3G Ex h IIB T4 Gc X, Motor: II 2G Ex db IIB T4 Gb NRTL certification No Items supplied Pumping unit completely mounted with inlet separator and emission condenser, with manual, 10 m cable without plug. Shatter and shock protection for glass parts are to be provided by the customer. Rated mains voltage range 1 230 V Mains frequency 1 50 Hz  für Zoom klicken

für Zoom klicken

Pump down graph 50 Hz (100 l volume)

Downloads

Chemistry vacuum systemMD 4C EX + AK + EK three stage,230 V / 50 Hz, with ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment (wiMD 4C EX +AK+EKChemistry vacuum systemEquipment

-

![PTFE tubing antistatic, KF DN 25/1000 mm]() KF DN 25, 1000 mm PTFE-tubing (antistatic) with small flanges

KF DN 25, 1000 mm PTFE-tubing (antistatic) with small flanges- PTFE (antistatic) / stainless steel

- Nominal width KF DN 25 mm | length 1000 mm

- Leak rate 1 x 10-4 mbar l/s

This might also interest you

-

![Chemistry diaphragm pump MZ 2C EXtwo stage, 230 V / 50 Hzwith ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment (with inert pur]() MZ 2C EX Chemistry diaphragm pump

MZ 2C EX Chemistry diaphragm pump- Ultimate vacuum 12 mbar

- ATEX conformity

- Oilfree & chemically resistant

![Chemistry vacuum system MZ 2C EX + AK+EKtwo stage, 230 V / 50 Hzwith ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment (with in]() MZ 2C EX +AK+EK Chemistry vacuum system

MZ 2C EX +AK+EK Chemistry vacuum system- Ultimate vacuum 12 mbar

- ATEX conformity

- Oilfree & chemically resistant

![ATEX diaphragm pump MD 4C EX]() MD 4C EX Chemistry diaphragm pump

MD 4C EX Chemistry diaphragm pump- Ultimate vacuum 3 mbar

- ATEX conformity

- Oilfree & chemically resistant

![Chemistry diaphragm pump MD 4C EX VARIOthree stage, 230 V / 50 Hzwith ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment (with i]() MD 4C EX VARIO VARIO® chemistry diaphragm pump

MD 4C EX VARIO VARIO® chemistry diaphragm pump- Ultimate vacuum 3 mbar

- ATEX conformity

- Oilfree & chemically resistant

![Chemistry pumping unitMD 4C EX VARIO +AK+EK,three stage, 230 V / 50 Hz,with ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment]() MD 4C EX VARIO +AK+EK VARIO® chemistry vacuum system

MD 4C EX VARIO +AK+EK VARIO® chemistry vacuum system- Ultimate vacuum 3 mbar

- ATEX conformity

- Oilfree & chemically resistant

![Chemistry diaphragm pump MV 10C EX VARIOfour stage, 230 V / 50 Hzwith ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment (with i]() MV 10C EX VARIO Chemistry diaphragm pump

MV 10C EX VARIO Chemistry diaphragm pump- Ultimate vacuum 2 mbar

- ATEX conformity

- Oilfree & chemically resistant

![Chemistry pumping unitMV 10C EX VARIO +AK+EK,four stage, 230 V / 50 Hzwith ATEX approval:pumping chamber (pumped gases):II 2G Ex h IIC T3 Gb Xenvironment (without inert purge gas):II 3G Ex h IIB T4 Gc Xenvironment]() MV 10C EX VARIO +AK+EK VARIO® chemistry diaphragm pump

MV 10C EX VARIO +AK+EK VARIO® chemistry diaphragm pump- Ultimate vacuum 2 mbar

- ATEX conformity

- Oilfree & chemically resistant